Worried about receiving low-quality Sodium Saccharin? Not sure how to verify your order is correct? This guide makes quality control clear and simple.

Check Sodium Saccharin quality by confirming it meets purity standards (USP/BP) on its CoA. Quality checks during production and a final pre-shipment inspection are vital to guarantee the product is right before it ships.

At FINETECH, quality is our promise. My clients have zero tolerance for quality problems. Avoiding these issues is why our business model is built around guaranteeing quality. Let's cover the key steps to check Sodium Saccharin quality.

What purity standards apply to Sodium Saccharin?

How do you define "good quality" for Sodium Saccharin? It starts with official standards. Let's look at the key benchmarks.

Food-grade Sodium Saccharin must meet strict purity standards from official sources like USP (United States), BP (British), or the FCC (Food Chemicals Codex).

Quality isn't a guess; it's a measurement against a standard. When ordering, you must specify which standard the product needs to meet. The most common are:

- USP (United States Pharmacopeia)1: A rigorous standard, widely used internationally.

- BP (British Pharmacopoeia)2: Another highly respected global standard.

- FCC (Food Chemicals Codex): Specifically for food ingredient purity.

- EP (European Pharmacopoeia): Essential for the EU market.

These standards set limits for purity (assay), appearance, and impurities like heavy metals. Specifying a standard (e.g., "Sodium Saccharin USP") gives you a clear quality target.

How to read Sodium Saccharin CoAs?

Your supplier sent a "CoA." What is it and how do you read it? Let's decode this key document.

A Certificate of Analysis (CoA) compares a batch's test results to the standard's limits. Ensure every "Result" on the CoA is within the "Specification" range. This confirms it passed testing.

The CoA is your proof of quality for a specific batch. It should list the product, batch number, and reference standard (e.g., USP).

The main part is a table with three columns:

- Test Item3: The specific test (e.g., Assay, Lead).

- Specification: The acceptable range or limit (e.g., Assay: 99.0-101.0%, Lead: ≤ 2 ppm).

- Result: The actual test result for your batch (e.g., Assay: 99.7%, Lead: <0.5 ppm).

Your job is simple: Check that every result is within the specification. A good CoA is your first line of quality defense. At FINETECH, we scrutinize every CoA.

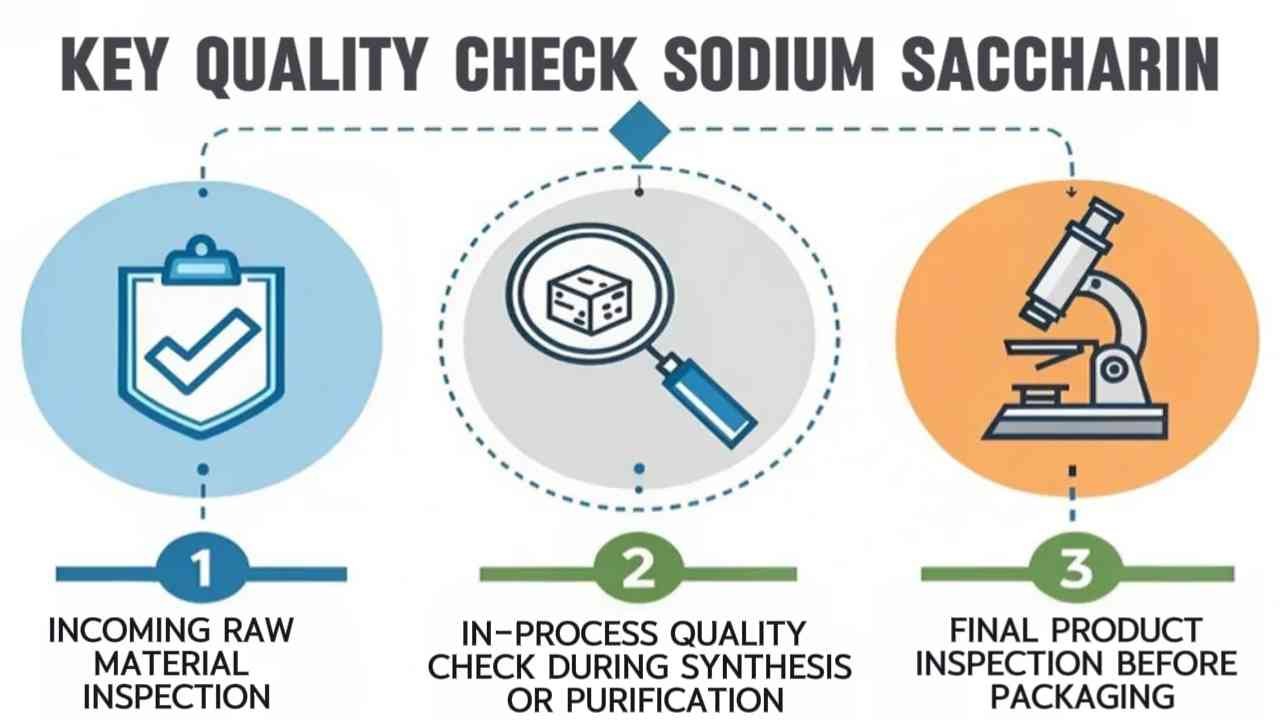

Which production steps need Sodium Saccharin checks?

How is quality guaranteed during production? Checks must happen at key stages, not just the end. Let's see where.

Quality checks are vital at three stages: incoming raw materials, during the synthesis/purification process (in-process), and on the final finished product before it's packaged.

Quality must be built into the process.

- Raw Material Control (IQC)4: The factory must test all incoming chemicals. Starting with pure materials is essential for a pure final product.

- In-Process Control (IPQC): Samples are tested during production. This allows for real-time adjustments and ensures consistency.

- Final Product Control (FQC)5: The finished batch is fully tested against the chosen standard (USP/BP). This generates the CoA and is the final quality gate before release.

A good factory has strong controls at all three stages. This is a key thing we audit at FINETECH.

Why inspect Sodium Saccharin before shipping?

The CoA looks good. Are you done? Not yet. A final physical check before shipping is critical. Here's why.

A Pre-Shipment Inspection (PSI) is a physical check of the quantity, packaging, and labeling before loading. It's your last chance to catch physical errors before the goods leave the factory.

The PSI prevents simple but costly mistakes. An inspector checks:

- Quantity: Are all the bags there?

- Packaging: Are the bags clean, undamaged, and the correct type?

- Labeling: Does the product name, batch number, and expiry date on the bags match the CoA and your order? This is crucial for customs and traceability.

- Loading Supervision: Watching the container get loaded ensures it's done right.

A PSI is a low-cost way to avoid major problems like short shipments, damaged goods, or customs rejection. It's a standard part of the FINETECH service to prevent these pain points.

How to handle faulty Sodium Saccharin?

What do you do if you receive a bad batch? Follow these professional steps to handle the issue.

If you get faulty Sodium Saccharin, immediately quarantine it, document the problem with photos and lab tests, and contact your supplier with the evidence. A good partner will work with you to resolve it.

Receiving bad product is a serious issue. Here’s the process:

- Isolate & Document: Quarantine the entire batch so it can't be used. Take photos of the problem and note all batch numbers.

- Test & Verify6: Send a sample to an independent third-party lab for unbiased testing. This provides strong evidence.

- Contact Supplier: Email a clear, professional report to your supplier with all evidence attached (photos, lab reports, CoA, etc.).

- Negotiate a Solution: A good supplier will offer a solution, such as a full replacement (at their cost) or a refund.

This can be a difficult process to manage from afar. As a local partner, FINETECH handles these claims directly, using our leverage to ensure a fast and fair resolution for our clients.

Conclusion

To check Sodium Saccharin quality, verify it meets official standards (USP/BP) by reading the CoA, and ensure inspections happen before shipping. A partner like FINETECH makes this process reliable.

-

Explore this link to understand the rigorous standards set by USP, crucial for ensuring product quality and safety. ↩

-

Discover the importance of BP standards in pharmaceuticals, ensuring quality and efficacy in products. ↩

-

Exploring common test items helps in understanding the quality assurance processes for products. ↩

-

Understanding IQC is crucial for ensuring the purity of materials, which directly impacts product quality. ↩

-

Exploring FQC helps grasp its role in quality assurance and compliance, ensuring products meet industry standards. ↩

-

Explore reliable testing methods to ensure product quality and avoid future issues. ↩