High MOQs can tie up your cash and create storage problems. This increases business risk and limits your flexibility. You need to find a balance between stock levels and cost efficiency.

The typical Minimum Order Quantity (MOQ) for Carboxymethyl Cellulose (CMC) is 1,000 kg (1 ton), which equals one pallet. Large manufacturers often require a full 20ft container (18-20 tons).

Understanding the logic behind MOQ helps you plan your procurement better. It also gives you leverage during price negotiations. Let's look at the technical and commercial factors that define these limits.

Why Do Suppliers Set MOQ for Carboxymethyl Cellulose (CMC)?

Small orders disrupt the efficiency of chemical production lines. Running large machinery for a small amount of product increases the cost per unit. Suppliers use MOQs to ensure their operations remain financially viable.

Suppliers set MOQs because CMC production is a continuous chemical process. Reactors are designed for multi-ton batches. Small runs cause excessive waste of raw materials and energy. MOQs also cover the fixed costs of laboratory quality testing and export documentation for each shipment.

Production Physics and Efficiency

The manufacturing of CMC involves reacting cellulose with sodium hydroxide and monochloroacetic acid in large-scale reactors. These machines operate most efficiently when full. A typical batch can be several tons. If a factory runs the equipment for only 100kg, the energy used for heating and mixing is almost the same as a full batch. This makes the production cost per kilogram of small batches extremely high.

Also, changing between different grades of CMC requires cleaning the entire system. This downtime is a significant loss for a factory. By setting an MOQ, the supplier ensures that the production time for a specific viscosity or purity grade justifies the machine setup time. This keeps the market price stable for all buyers.

Administrative and Quality Control Costs

Every batch of CMC must undergo laboratory testing to verify viscosity, purity, and pH levels. The labor and chemical costs for these tests are the same for a 500kg order as they are for a 20-ton order. Similarly, the administrative work for export—such as the Bill of Lading, Certificate of Origin, and customs clearance—involves fixed fees.

| Cost Factor | Small Order (500kg) | Large Order (20 Tons) |

|---|---|---|

| Machine Setup | High cost per kg | Low cost per kg |

| Laboratory Testing | Fixed batch fee | Fixed batch fee |

| Cleaning Downtime | High impact | Low impact |

| Documentation | Significant per ton | Negligible per ton |

How Can Buyers Negotiate Lower MOQ for Carboxymethyl Cellulose (CMC)?

Strict MOQs can be a barrier when you want to test a new market. You may not be ready to commit to a full pallet or container. There are technical ways to get the flexibility you need from your supplier.

Buyers can negotiate lower MOQs by selecting standard viscosity grades that the supplier already has in stock. You can also offer to pay a small price premium to cover repacking costs. Consolidating different food additives into one shipment is another effective way to meet the supplier's minimum requirements.

Leveraging Existing Inventory

The easiest way to reduce MOQ is to avoid custom specifications. Factories produce common grades like 2500cps or 5000cps frequently. If a supplier has a large stock of a standard grade for other clients, they are more willing to sell smaller portions of that stock. If you require a unique viscosity or a specific degree of substitution, the factory must start a new run, which always triggers a high MOQ.

I suggest checking the supplier’s current stock list. Using an "off-the-shelf1" grade for your initial production runs allows you to buy exactly what you need. This reduces the risk of the powder clumping in your warehouse during long storage periods in humid climates like Indonesia or Vietnam.

Consolidation and Partnership Growth

| Negotiation Strategy | Implementation | Outcome |

|---|---|---|

| Standardization | Use common viscosity grades | Lowers MOQ barrier |

| Mixed Shipments | Combine CMC with other additives | Meets total weight targets |

| Premium Pricing | Pay 5-10% more for small lots | Offsets supplier's extra labor |

| Trial Clauses | Request a one-time trial MOQ | Permits low-risk testing |

How Does MOQ Affect Carboxymethyl Cellulose (CMC) Unit Cost?

Order volume has a direct impact on the final price you pay per kilogram. Small orders are almost always more expensive because the fixed costs are spread over fewer units. You must calculate the total landed cost to understand the true price of your CMC.

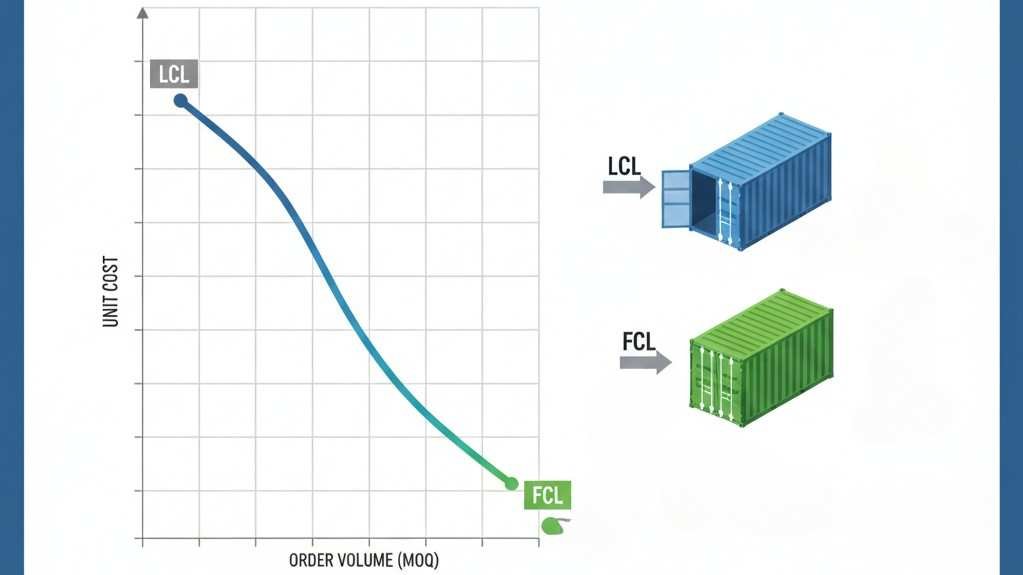

MOQ and unit cost have an inverse relationship. Larger orders benefit from economies of scale in manufacturing and bulk packaging. More importantly, shipping a Full Container Load (FCL) is significantly cheaper per ton than shipping Less than Container Load (LCL) due to reduced port handling and freight fees.

Shipping and Logistics Variables

Shipping costs are a major component of the price for heavy additives like CMC. If you order only 1 ton, it must be shipped as LCL. This involves consolidation at the port, which adds extra handling fees and higher freight rates per cubic meter. When you increase the order to a full 20ft container (18-20 tons), you avoid these extra fees. The freight cost per kilogram2 can drop by as much as 40% when moving from LCL to FCL.

In my experience with exports to Saudi Arabia and Europe, the price difference at the destination can be surprising. A "cheap" 1-ton order often ends up costing more per bag than a larger order once you add in the customs clearance and local trucking fees. These fixed fees do not change based on weight, so they hit small orders much harder.

Packaging and Processing Labor

Factories use automated bagging machines for large orders. Small orders often require workers to manually pull bags, relabel them, or secure them onto pallets. This manual labor adds to the cost. Also, factories get better pricing on the raw cellulose and the packaging materials when they produce in large volumes.

| Order Quantity | Shipping Method | Cost Efficiency |

|---|---|---|

| 500kg - 1 Ton | LCL Sea / Air | Low (High fees per kg) |

| 3 Tons - 5 Tons | LCL Sea | Moderate |

| 18 Tons - 20 Tons | FCL (Full Container) | High (Lowest fees per kg) |

| 100+ Tons | Bulk Contracts | Maximum Discount |

What MOQ Is Suitable for Trial Carboxymethyl Cellulose (CMC) Orders?

Testing a new grade of CMC in a laboratory is the first step, but it is not enough. You need to see how the ingredient behaves in your industrial mixers and heat exchangers. This requires a specific amount of material to run a valid trial.

A suitable MOQ for a pilot production trial is between 500kg and 1 ton. While a 1kg sample is enough for lab tests, a full pallet is necessary to test solubility, viscosity stability, and texture in large-scale factory equipment. This ensures the grade works with your specific machinery and process.

Lab Beakers vs. Industrial Mixing

A laboratory test in a 500ml beaker does not show how CMC will behave in a 5,000-liter tank. In a large tank, the shear force3 and the way the powder is added can cause "fish eyes" (clumping). A 500kg trial allows your production team to run the machines at full speed. This helps you identify if you need a different mesh size or a different dispersion method4 before you commit to a full container.

I have seen many wholesalers in Russia and Malaysia order a single pallet to provide samples to their local clients. This is a low-risk way to prove that the quality is consistent across a whole pallet, not just a small sample bag. It gives the end-user confidence that the CMC will perform reliably in their daily operations.

Validating Final Product Texture

| Trial Scale | Typical Quantity | Primary Goal |

|---|---|---|

| Laboratory | 500g - 2kg | Chemical spec verification |

| Pilot Plant | 250kg - 500kg | Machinery compatibility |

| Market Sample | 1 Ton | Customer feedback/Shelf-life |

| Commercial | 18+ Tons | Scaled manufacturing |

When Does Higher MOQ Benefit Carboxymethyl Cellulose (CMC) Buyers?

Higher MOQs are not always a disadvantage. In a volatile market, buying in bulk can protect your company from sudden price spikes or supply shortages. Strategic buyers use volume to their advantage to secure their supply chain.

Higher MOQs benefit buyers by locking in prices during market inflation and ensuring inventory during shipping delays. Buying full containers also lowers the risk of transit damage compared to LCL shipments. Furthermore, high-volume buyers receive priority from factories during periods of raw material shortages.

Price Hedging and Supply Security

The prices of raw materials like wood pulp and cotton linters fluctuate constantly. If you buy in small MOQs every month, your costs will change every time. A high MOQ allows you to lock in a price for several months of stock. This makes your financial planning more predictable. In regions like the UAE or Qatar, where shipping times can be long, having a large buffer stock is the only way to prevent a factory shutdown if a ship is delayed.

I have found that high-volume buyers are treated as "strategic partners5." If there is a power shortage or a raw material limit in China, the factory will always fulfill the largest contracts first. This priority is essential for large companies that cannot afford to stop their production lines for even one day.

Reducing Transit Damage Risk

LCL shipments (small MOQs) are handled multiple times. They are loaded and unloaded at several consolidation points. This increases the risk of punctured bags and moisture exposure. FCL shipments (high MOQs) are loaded at our factory and only opened at your warehouse. This significantly reduces the chance of product loss.

| Advantage Category | Small MOQ (LCL) | High MOQ (FCL) |

|---|---|---|

| Price Protection | None (Market price) | High (Locked price) |

| Inventory Risk | High (Stock-out risk) | Low (Buffer stock) |

| Shipping Safety | Lower (More handling) | Higher (Direct delivery) |

| Supplier Service | Standard Support | Priority Support |

Conclusion

The typical MOQ for CMC is 1 ton, but flexibility is possible. Balancing your order size with cost and risk is the key to successful food additive procurement.

-

Exploring off-the-shelf options can help you save time and money, making your production process more efficient. ↩

-

Exploring this topic can provide insights into cost-saving strategies for shipping heavy materials. ↩

-

Understanding shear force is crucial for optimizing CMC dispersion in large tanks, ensuring consistent quality and performance. ↩

-

Exploring effective dispersion methods can enhance the mixing process, leading to better product quality and efficiency in production. ↩

-

This link will provide insights into the advantages of being recognized as a strategic partner, especially in times of supply shortages. ↩