An unstable supply of Sodium Erythorbate leads to meat oxidation and financial loss. These delays ruin product quality and customer trust. You need a reliable strategy to manage your raw material inventory.

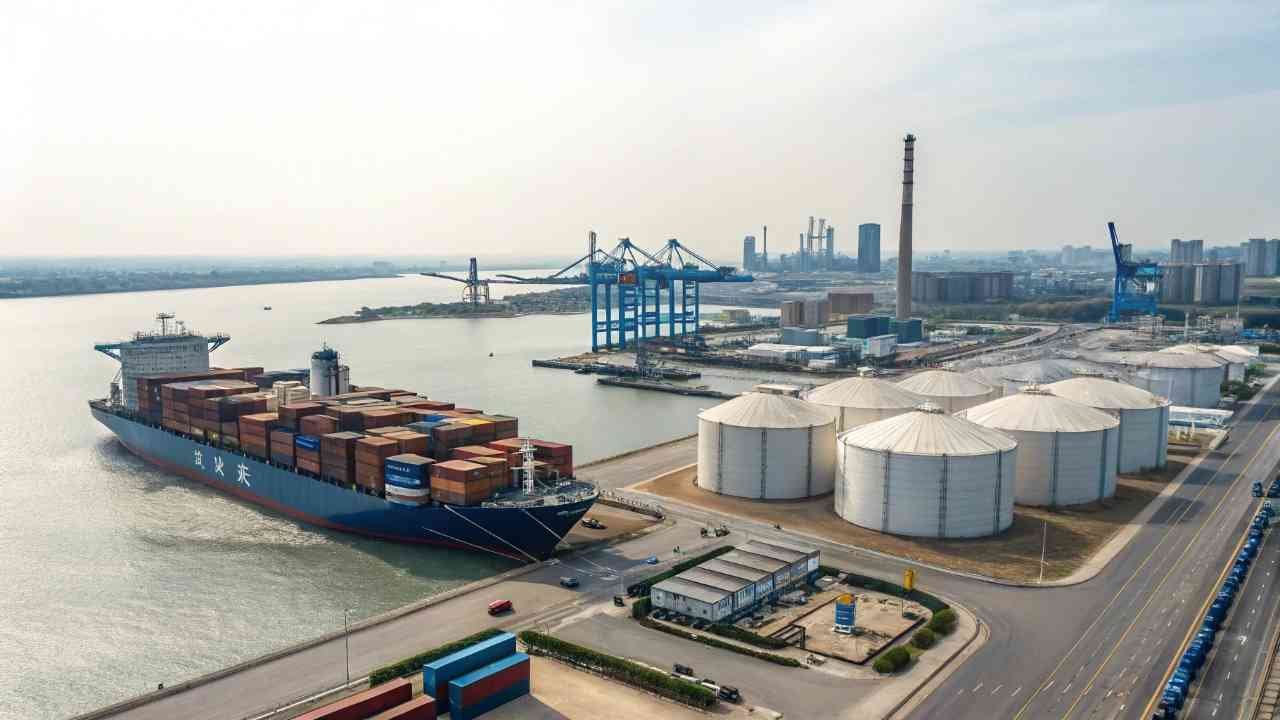

Sodium Erythorbate supply is managed through a global network centered in China. Buyers use demand forecasting, buffer stocks, and strategic partnerships with exporters to stabilize costs. These methods ensure a continuous flow of high-quality antioxidants for food processing and beverage stabilization across international markets.

I see many wholesalers struggle with sudden price jumps and stockouts. I want to explain the global supply chain to help you improve your procurement results.

What Are the Current Price Trends of Sodium Erythorbate?

Fluctuating prices of Sodium Erythorbate make budget planning difficult. Sudden spikes increase your production costs and lower your margins. You must understand the market drivers to protect your business profits.

Sodium Erythorbate prices are driven by the cost of corn and Chinese environmental regulations. Current trends show periodic volatility due to shipping costs and energy prices. Monitoring these factors helps buyers time their purchases to secure competitive pricing for their bulk orders.

Factors Driving Market Prices

The price of Sodium Erythorbate starts with the cost of corn. Manufacturers use corn to create glucose for fermentation. When corn prices go up in China, the price of Sodium Erythorbate follows. I also watch energy costs in production provinces. Fermentation requires a lot of electricity and heat. If energy prices rise, factories increase their selling prices to stay profitable. Environmental compliance1 in China also plays a huge role. The government often checks factories for waste management. If a factory stops production for an inspection, the total supply drops. This causes the market price to rise quickly.

I stay in close contact with production teams to see these changes early. This allows me to warn my food industry clients2 before prices increase. Freight costs are another major part of the final price. Since the pandemic, shipping rates have been very unstable. A container from China to Saudi Arabia or Germany can change in price by thousands of dollars in one month. This affects the "landed cost" of the product. Buyers should look at the total cost, not just the factory price. I recommend using Full Container Loads (FCL) to keep the shipping cost per kilogram as low as possible. Small orders (LCL) usually have higher handling fees which drive up the unit price.

| Price Driver | Impact Level | Duration of Effect |

|---|---|---|

| Corn Raw Material | High | Long-term |

| Energy Costs | Medium | Seasonal |

| Environmental Rules | High | Unpredictable |

| Shipping Rates | Medium | Short-term |

Which Countries Are Leading Sodium Erythorbate Production?

Relying on the wrong manufacturing hub leads to inconsistent quality and shipping delays. These logistics gaps hurt your supply chain and production. You need to know where the most reliable capacity is located.

China is the global leader in Sodium Erythorbate production, providing over 80% of the world's supply. Other hubs exist in Europe and North America, but China offers the most competitive pricing and the largest scale for B2B wholesale buyers worldwide.

China’s Dominance in Fermentation

China has the most advanced fermentation technology for food antioxidants. Factories use large-scale reactors to produce thousands of tons of Sodium Erythorbate every year. This scale allows them to keep the cost per unit very low. Most of these factories are located in provinces where corn is grown. This location reduces the cost of transporting raw materials. I work with these top-tier factories to ensure products meet international standards like ISO and HACCP. Buyers from Indonesia, Vietnam, and Korea depend on Chinese production. Proximity to these markets means shipping is fast and costs are lower.

In Europe, countries like Russia and Germany buy heavily from China because local production is more expensive. The technology in Chinese factories has improved. We now produce Sodium Erythorbate with 99% purity and excellent stability. This makes China the first choice for most food additive wholesalers3. While other countries produce Sodium Erythorbate, their capacity is much smaller. They often focus on local markets. Chinese manufacturers are focused on the global market. They are used to meeting many different quality standards. We provide HALAL and KOSHER certificates for clients in the Middle East. We ensure products meet the Food Chemicals Codex (FCC) standards. This global focus makes China the most reliable source for large company buyers.

| Region | Market Share | Main Advantage |

|---|---|---|

| China | 80%+ | Scale and low cost |

| Europe | < 10% | Local supply for EU |

| North America | < 5% | Specialized uses |

| Other | < 5% | Domestic consumption |

How Does Demand Affect Sodium Erythorbate Availability?

Sudden spikes in demand lead to inventory shortages and high prices. These gaps stop your production lines and delay orders. You need to align your orders with market cycles to maintain a steady supply.

Global demand for Sodium Erythorbate is driven by the meat and beverage industries. During peak seasons like summer and year-end holidays, availability can tighten. Buyers must plan orders ahead to avoid shortages during these high-consumption periods in the food industry.

Seasonality in Meat and Beverages

Demand for Sodium Erythorbate is not the same all year. Meat consumption goes up during the summer BBQ season and Christmas holidays. Sodium Erythorbate is vital for meat processing4 and keeping it pink. If you wait until these busy months to buy, the factory might be full. I suggest my clients in the UAE and Qatar order stock three months before their peak holidays. This ensures they have a buffer in their warehouse. The beverage industry also uses Sodium Erythorbate to prevent oxidation in juices and sodas. Demand for these drinks increases in hot weather.

In Southeast Asia, demand stays high for most of the year. Buyers must watch trends in their local markets. If your customers sell more product, you will need more Sodium Erythorbate. I help my buyers track consumption patterns to create a better reorder schedule. More companies are using Sodium Erythorbate to replace synthetic preservatives. It is a safer antioxidant for many food products. This clean label trend5 is growing in Europe and North America. As more food brands switch to Sodium Erythorbate, total global demand increases. This puts pressure on factories. When demand grows faster than production, prices go up and lead times get longer. Staying ahead of these trends is the only way to avoid being caught without stock.

| Sector | Usage Level | Seasonal Peak |

|---|---|---|

| Meat Curing | Very High | Summer & Winter |

| Beverages | High | Hot Weather |

| Seafood | Medium | Year-round |

| Industrial | Low | Varies |

What Are the Challenges in Importing Sodium Erythorbate?

Complex import rules and shipping delays lead to stuck cargo and extra fees. These logistical hurdles damage your efficiency and waste money. You must identify these challenges before they occur to ensure smooth delivery.

Challenges in importing Sodium Erythorbate include strict customs documentation, HALAL certifications, and maritime logistics issues. Meeting local food safety regulations in Europe, the Middle East, or Southeast Asia is vital for successful importation and distribution of the product.

Documentation and Certification Requirements

Customs officers in countries like Saudi Arabia or Indonesia are very strict. They require a Certificate of Analysis (COA) for every batch. They also check for HALAL certificates from recognized bodies. If your paperwork is wrong, your container will sit at the port. This costs you money in storage fees. I make sure all documents are perfect before the ship leaves China. We provide the MSDS, Invoice, and Packing List in the correct format for your specific country. Each region has its own limits for impurities like lead or arsenic. We test our Sodium Erythorbate to meet the rules of the EU and the FDA.

If you buy from a trader who does not understand these rules, you risk having cargo rejected by health inspectors. I suggest that buyers verify technical specs before they pay. This prevents legal problems in your home market. Port congestion is another major problem. Ships are often delayed because the port is too busy. This is common in Southeast Asia and the Middle East. If you do not have extra stock, a two-week delay can stop your factory. I work with multiple shipping lines to find the fastest routes. We track the cargo daily and give updates to our buyers. Transparency helps you manage inventory even when the logistics market is difficult.

| Import Hurdle | Common Location | Solution |

|---|---|---|

| Document Errors | Middle East | Pre-check by exporter |

| Safety Testing | Europe / USA | Batch-specific COA |

| Port Delays | Southeast Asia | 2-week buffer stock |

| High Freight | Global | FCL shipments |

How Can Buyers Secure a Stable Sodium Erythorbate Supply?

An unstable supply chain ruins customer relationships and stops business growth. You cannot afford to run out of materials in a competitive market. A strategic procurement plan secures your success and keeps prices stable.

Buyers secure a stable supply by establishing long-term contracts and maintaining safety stocks. Partnering with experienced exporters like FINETECH ensures product consistency. Monitoring Chinese market trends and diversifying shipping methods reduces the risk of supply chain disruptions for your business.

Establishing Long-Term Relationships

The best way to get a stable supply is to work with the same supplier long-term. At FINETECH, I prioritize my regular clients when the market is tight. If there is a shortage, I make sure long-term partners get their orders first. This relationship also leads to better pricing over time. We understand your quality needs and shipping preferences. This reduces mistakes and makes the process faster. I suggest buyers move away from "spot buying" and look for a partner they can trust for several years. You should always have a "safety stock" in your own warehouse.

I recommend keeping at least one month of extra supply. This protects you if a ship is late or a factory has a production delay. Planning orders three months in advance is a good habit. This gives us time to produce, test, and ship your Sodium Erythorbate. For clients in Korea and Vietnam, this planning has prevented many stockouts. Data-driven procurement is much safer than guessing your needs every month. I send regular market updates to my clients. I tell them about corn prices and factory status in China. When you have this data, you can buy when the price is low. You can also avoid buying during a peak if you have enough stock. Monitoring signals allows you to be proactive. A stable supply is about having product at the right price.

| Supply Strategy | Action Step | Goal |

|---|---|---|

| Long-term Contract | 6-12 month agreements | Price stability |

| Safety Stock | Keep 20% extra stock | No production stops |

| Forecasting | 3-month demand plan | Priority at factory |

| Quality Standard | Batch sample testing | Product consistency |

Conclusion

Managing Sodium Erythorbate supply requires understanding price trends, production hubs, and demand cycles. Strategic planning and reliable partnerships ensure you have the materials needed to grow your business successfully.

-

Environmental compliance ensures factories adhere to laws that prevent production stoppages and supply disruptions. ↩

-

Food industry clients include manufacturers, brands, and large-scale procurement teams tracking market trends. ↩

-

Food additive wholesalers distribute specialty ingredients like Sodium Erythorbate to global markets. ↩

-

Meat processing uses Sodium Erythorbate as an antioxidant to maintain color and extend shelf life. ↩

-

The clean label trend emphasizes transparent, recognizable ingredients and influences procurement strategies. ↩