Unstable pricing for Sodium Erythorbate disrupts your budget and profit margins. This financial uncertainty makes procurement risky for your business. You need to understand the pricing structure to secure competitive rates.

Sodium Erythorbate pricing is determined by raw material costs like corn-derived glucose and factory energy expenses in China. International logistics, currency fluctuations, and export policies also play a major role. Large-volume buyers typically receive discounts, while seasonal demand peaks drive prices higher across the global market.

I have managed many wholesale orders for food additives. I want to explain the specific factors that decide the price you see on your proforma invoice.

What Factors Influence Sodium Erythorbate Prices?

Volatile production costs lead to sudden price hikes in the market. These spikes hurt your bottom line and planning. Understanding these factors helps you predict price changes before they actually occur.

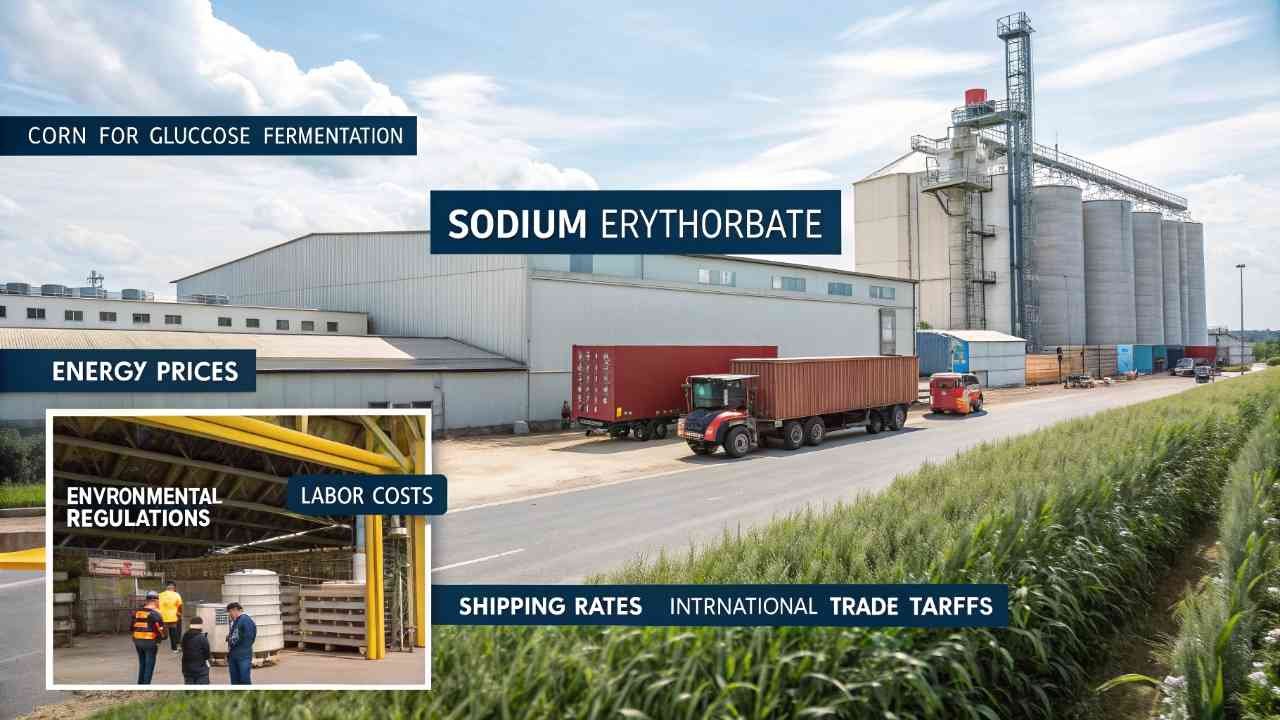

The primary factors influencing Sodium Erythorbate prices are the cost of corn for glucose fermentation and energy prices in China. Environmental regulations and labor costs also affect factory output. Furthermore, shipping rates and international trade tariffs directly impact the final landed cost for global buyers.

Raw Materials and Energy Drivers

Sodium Erythorbate is produced through the fermentation of glucose. In China, glucose mostly comes from corn. This means the price of corn is the most important factor. If the corn harvest is poor, the price of glucose goes up. I watch the Chinese agricultural market closely because it sets the base price for the year. When the raw material cost rises, the factory must increase the price to cover its expenses. This is a direct link that every food buyer1 should monitor.

Energy is another major cost for factories. The fermentation process requires a lot of electricity and steam. If coal or gas prices rise, production costs go up. Also, the Chinese government has strict environmental laws. Sometimes factories must upgrade their waste treatment systems. These upgrades cost money and the factory passes these costs to the buyer. In some cases, factories must limit production during high-pollution days. This lower supply leads to higher prices in the international market. I see that labor costs in China are also rising slowly, which affects the final price. Finally, the exchange rate between the Chinese Yuan and the US Dollar changes every day. If the Yuan gets stronger, the price in Dollars usually goes up.This information is vital for supply chain management2 professionals.

| Factor Category | Main Driver | Impact on Price |

|---|---|---|

| Raw Material | Corn and Glucose prices | Very High |

| Energy | Electricity and Fuel costs | High |

| Regulation | Environmental compliance | Moderate to High |

| Finance | USD/CNY Exchange Rate | Moderate |

How Does Supply Chain Affect Sodium Erythorbate Cost?

Logistics bottlenecks increase your inventory costs and cause delivery delays. These supply chain issues reduce your business efficiency. Better supply chain management is the key to lower your total procurement expenses.

Supply chain efficiency affects costs through freight rates, port handling fees, and storage expenses. Moving from LCL to FCL significantly reduces the cost per kilogram. Additionally, the proximity of the factory to major ports in China helps lower domestic transportation charges for international shipments.

Impact of Shipping and Logistics

I always suggest that buyers look at the difference between LCL and FCL. LCL stands for Less than Container Load. It means your goods share a container with other products. This is often more expensive because of high port handling fees. FCL stands for Full Container Load. When you buy a full 20ft container of Sodium Erythorbate, the shipping cost per ton is much lower. For my clients in the Middle East and Southeast Asia, buying in bulk is the best way to save on logistics costs3.

The location of the factory matters for the final price. If a factory is far from the port, the truck transport inside China is expensive. I choose factories that have good connections to major ports like Qingdao or Tianjin. This reduces the inland freight cost. Also, port congestion can cause delays. When ports are busy, shipping lines raise their rates. I keep track of these shipping trends4 to help my clients avoid the busiest and most expensive shipping seasons. Holding stock in a warehouse costs money for space and insurance. If you plan your supply chain poorly, you might have too much or too little stock. Both situations increase your costs. I work with my clients to create a delivery schedule that reduces storage fees and ensures the product remains fresh.

| Shipping Type | Handling Fees | Cost per Ton | Best For |

|---|---|---|---|

| LCL Sea Freight | High | High | Small traders |

| FCL Sea Freight | Low | Low | Large wholesalers |

| Air Freight | Very High | Very High | Emergency orders |

| Rail Freight | Moderate | Moderate | Landlocked regions |

What Payment Terms Are Common for Sodium Erythorbate Trade?

Poor payment terms can tie up your working capital and slow your growth. Financial risk is a major concern for B2B buyers in the additive market. Choosing the right terms balances your company's safety and liquidity.

Common payment terms include T/T (Telegraphic Transfer) with a 30% deposit and 70% against the Bill of Lading. L/C (Letter of Credit) is used for large company orders to ensure security. Some established partners may use D/P or CAD terms depending on their credit history and local regulations.

Standard Payment Methods

T/T is the most common method I use. Usually, the buyer pays a 30% deposit to start production. This shows commitment to the factory. The remaining 70% is paid after I send a copy of the Bill of Lading. This document proves the goods are on the ship. This method is fast and has low bank fees. It works well for most wholesalers in Southeast Asia and Europe. It is simple and keeps the process moving quickly. For very large orders, many company buyers prefer an L/C. This is a guarantee from the bank. It says the bank will pay the seller once all documents are correct.

Bank fees for L/C are higher and the paperwork is more complex. I help my clients prepare all the documents like the COA, Packing List, and Invoice to meet L/C requirements. This ensures there are no delays in payment or delivery. As I build trust with my regular clients, we can discuss more flexible terms. For example, some clients use "Cash Against Documents" (CAD). This means they pay when their bank receives the original papers. We also check the credit history of our long-term partners. If they have a good record, we can offer better terms. This helps them manage their cash flow. But for new clients, a deposit is always required to protect the factory's production costs.

| Method | Safety for Buyer | Speed | Bank Fees |

|---|---|---|---|

| T/T Deposit | Moderate | Fast | Low |

| L/C at Sight | High | Slow | High |

| CAD / DP | Moderate | Moderate | Moderate |

| Open Account | Very High | Fast | Low |

How Can Buyers Negotiate Sodium Erythorbate Prices?

Overpaying for raw materials reduces your competitiveness in the food industry. This waste of money hurts your company’s growth. Learning to negotiate effectively helps you secure better margins and more profit.

Buyers negotiate prices by committing to larger annual volumes or signing long-term supply contracts. Combining multiple food additives into one shipment also provides leverage. Flexibility in delivery dates and using standard packaging can lead to lower quotes from manufacturers and exporters.

Negotiation and Cost Saving

The best way to get a lower price is to buy more. Factories love large, stable orders. If you can commit to a certain number of tons per year, I can negotiate a lower rate for you. Even if you don't ship it all at once, an annual contract helps the factory plan its production. This stability is valuable. I use these annual volumes to get the best possible price from the production line. This is a common strategy for large food additive distributors5. I also suggest that my clients buy different products together.

You can buy Sodium Erythorbate and Carboxymethyl Cellulose (CMC) in the same order. This increases your total business value with us. It also makes shipping more efficient. When I see a large multi-product order, I have more room to offer a discount. I watch the market cycles to tell my clients when to buy. If the price is low because of a good corn harvest, I suggest they buy extra stock. Negotiation is often about timing. If you are not in a rush, you have more power. I also suggest using standard packaging. If you want custom bags, the cost goes up. Using the factory's standard 25kg bags is the most cost-effective choice for every buyer.

| Tactic | Implementation | Result |

|---|---|---|

| Volume Commitment | Sign a 12-month contract | Lower price per kg |

| Product Mixing | Buy 3+ additives together | Overall discount |

| Off-peak Ordering | Order during quiet months | Better factory attention |

| Standard Specs | Use standard 25kg bags | No extra packing fees |

How Does Market Demand Change Sodium Erythorbate Pricing?

Sudden demand spikes lead to shortages and inflated pricing. These market shifts make it hard for you to maintain a steady supply. Watching demand cycles helps you buy at the right time and avoid high costs.

Market demand changes pricing through seasonal peaks in the meat and beverage industries. During the summer and year-end holidays, increased consumption drives up the price. When global demand exceeds factory capacity in China, manufacturers raise prices to manage their limited production slots.

Market Cycles and Demand

Sodium Erythorbate is used a lot in meat processing and beverages. Demand for these products is not the same all year. For example, meat consumption goes up during the summer BBQ season and the Christmas holidays. Many meat factories buy their antioxidants a few months before these peaks. This causes a surge in demand. If you wait until the last minute, you will pay a higher price. I help my clients plan their orders 3 to 4 months ahead of their local busy seasons. I also monitor how other antioxidants are doing in the market6.

If the price of Vitamin C (Ascorbic Acid) goes up, many buyers switch to Sodium Erythorbate. This sudden switch increases the demand for Sodium Erythorbate and drives its price up too. It is important to look at the whole antioxidant market. Also, as more countries move toward processed food, the global demand for stabilizers and antioxidants grows. This long-term growth keeps the floor price of Sodium Erythorbate stable. Sometimes demand is higher than what all the factories can produce. This happens if some factories are closed for repairs or inspections. When the supply is low and demand is high, the price rises very fast. I stay in touch with factory managers to know their production schedules and warn my clients early.

| Season | Demand Level | Price Trend | Reason |

|---|---|---|---|

| Q1 (Jan-Mar) | Moderate | Stable | Post-holiday slowdown |

| Q2 (Apr-Jun) | High | Rising | Summer BBQ preparation |

| Q3 (Jul-Sep) | Moderate | Stable | Mid-year lull |

| Q4 (Oct-Dec) | Very High | High | Year-end holiday peak |

Conclusion

Sodium Erythorbate pricing depends on raw materials, logistics, and market cycles. I help my clients manage these variables to ensure the best value and a stable supply chain for their business.

-

Food buyers need to track raw material prices and supply fluctuations to plan purchases efficiently. ↩

-

Supply chain management ensures timely delivery, cost control, and minimal disruption in food production. ↩

-

Logistics costs include freight, port handling, and warehouse fees, affecting overall procurement budgets. ↩

-

Shipping trends help predict peak seasons, port congestion, and cost fluctuations for international trade. ↩

-

Food additive distributors manage bulk purchases and multiple product lines to optimize cost and delivery. ↩

-

Monitoring market trends for antioxidants and stabilizers helps buyers time their purchases strategically. ↩