Poor quality Sodium Erythorbate causes meat oxidation and ruins food texture. These failures lead to customer complaints and financial loss. Strict quality control ensures your food products stay fresh and safe.

Sodium Erythorbate quality is controlled through precise fermentation, high-purity filtration, and strict adherence to international standards like FCC and E316. Manufacturers use laboratory testing for assay levels, heavy metals, and moisture to ensure every batch meets safety requirements for food and beverage applications.

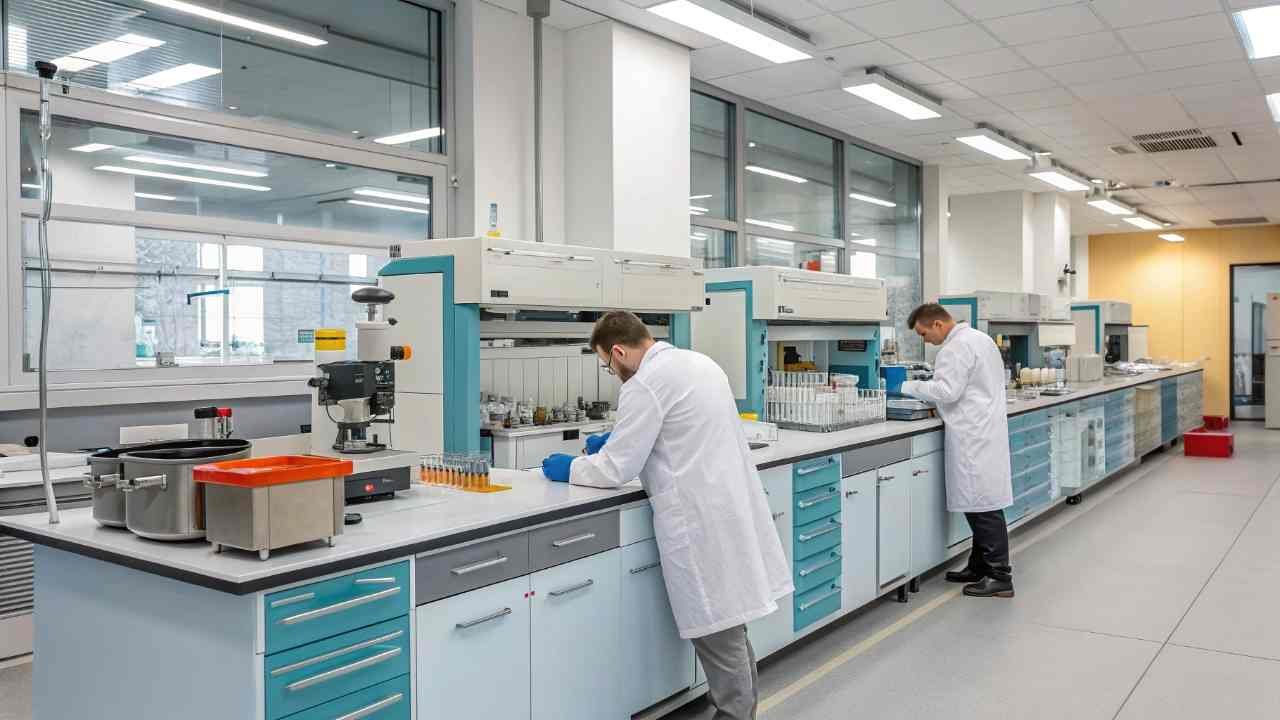

I manage the factory selection and quality oversight for many global buyers. I want to explain the technical steps we take to ensure every bag of Sodium Erythorbate meets your industrial standards.

What Are the Key Quality Specifications of Sodium Erythorbate?

Incorrect specifications lead to product instability and short shelf life. These technical errors waste your money and manufacturing resources. Understanding key metrics helps you buy the right material for your factory.

The key quality specifications for Sodium Erythorbate include an assay level of 98% to 100.5%, a pH value between 5.5 and 8.0, and a specific rotation of +95.5° to +98.0°. Limits on heavy metals like lead and arsenic are also critical for food safety.

Understanding Purity and Safety Metrics

The assay is the most important number on your Certificate of Analysis (COA). It shows the percentage of active Sodium Erythorbate in the powder. For food use, this must be nearly 100%. If the assay is low, it means impurities or moisture are diluting the product. This reduces the antioxidant1 power in your meat curing or beverage stabilization process. You would need to use more powder to get the same result. This increases your production costs2. I always check that our batches stay at the high end of the 98% to 100.5% range.

Specific rotation is another marker of purity. It measures how the chemical structure affects light. If the rotation is outside the +95.5° to +98.0° range, the product might be damaged. We also check the physical appearance. Sodium Erythorbate should be a white or slightly yellow crystalline powder. If it looks dark, oxidation has already started. Food safety also depends on what is not in the product. We set strict limits for heavy metals3 Lead must be below 2 mg/kg. Arsenic must be below 3 mg/kg. Our factories use advanced filtration to remove these contaminants during the crystallization stage. We also test for moisture. If moisture is above 0.25%, the powder can clump. This makes it hard to measure the correct dosage.

| Metric | Specification Range | Why It Matters |

|---|---|---|

| Assay (Dry Basis) | 98.0% – 100.5% | Determines antioxidant strength |

| Specific Rotation | +95.5° – +98.0° | Confirms chemical purity |

| pH Value (1 in 20) | 5.5 – 8.0 | Affects reaction in food |

| Heavy Metals (as Pb) | Max 10 mg/kg | Ensures consumer safety |

| Loss on Drying | Max 0.25% | Prevents clumping |

How Is Purity Tested in Sodium Erythorbate Production?

Impurities in antioxidants can cause toxic reactions or bad odors in food. These risks damage your brand and consumer health. Rigorous testing is the only way to guarantee a pure and safe product.

Purity is tested using high-performance liquid chromatography (HPLC) and titration to measure active sodium salt content. Labs also conduct atomic absorption spectroscopy (AAS) to detect trace heavy metals and moisture analysis to ensure the crystalline structure is stable for industrial use.

Analytical Methods for Quality Assurance

In our quality control process, we use HPLC to look at the molecular level. This machine separates the different parts of a sample. It helps us see if there are any unwanted by-products from the fermentation process. If the HPLC graph shows extra peaks, the batch is not pure enough. We also use titration. This is a classic chemical method. A chemist adds a reagent to a solution until a reaction occurs. This tells us the exact concentration of the sodium salt. This double-check system ensures our COA data is accurate.

Heavy metal testing requires sensitive equipment. We use Atomic Absorption Spectroscopy (AAS). These machines find even tiny amounts of lead or arsenic. This detail is necessary to meet rules in Europe and the USA. Wholesalers in Southeast Asia and the Middle East also demand these reports. I personally review these lab logs to make sure no batch with high metal levels leaves the factory. Purity is also about biology. Sodium Erythorbate is made by fermentation using corn glucose. We must test for bacteria, yeast, and mold. High levels of microbes during production can ruin the batch. We also test solubility4. Pure Sodium Erythorbate should dissolve completely in water. If there is sediment, the filtration stage was not good enough.

| Test Type | Method | Target |

|---|---|---|

| Active Content | HPLC / Titration | 99% minimum |

| Heavy Metals | AAS | Meets FCC standards |

| Moisture Content | Moisture Meter | Below 0.25% |

| Microbiology | Incubation Plates | Zero pathogens |

| Solubility | Water dissolution | Clear, no residue |

What Standards Ensure Food-Grade Sodium Erythorbate?

Using uncertified additives leads to legal penalties and rejected shipments. These regulatory hurdles stop your business growth. International standards provide a safety framework for global trade and protect your company reputation.

Food-grade Sodium Erythorbate must meet the Food Chemicals Codex (FCC), European Union (E316), and JECFA standards. Compliance with ISO 22000, HACCP, and certifications like HALAL and KOSHER ensures the manufacturing process follows global hygiene and safety protocols.

Regulatory Frameworks and Hygiene Certifications

The Food Chemicals Codex (FCC) is the main guide for the USA and many other regions. It lists the purity levels needed for a chemical to be called "food grade." In Europe, we follow the E316 standard. While these rules are similar, they can have small differences in testing methods. Our products meet both standards at the same time. This allows our clients to sell their finished products in different global markets. JECFA also provides safety evaluations. They set the "Acceptable Daily Intake" (ADI) for humans.

Beyond chemical specs, the factory must have a safe management system. ISO 22000 and HACCP are the gold standards. HACCP means the factory looks at every step of production to find where a mistake could happen. For example, they use metal detectors on the packaging line. This prevents metal pieces from falling into the bags. These systems stop accidents before they reach the buyer. I visit the factories to check if they follow these plans. For my clients in the Middle East and Southeast Asia, HALAL certification5 is mandatory. This proves no forbidden substances are used. Because Sodium Erythorbate is made from corn, it is naturally plant-based. But the factory must still be certified to avoid cross-contamination. KOSHER certification is also common for North American and European markets.

| Standard / Cert | Region | Focus Area |

|---|---|---|

| FCC / USP | Global / USA | Chemical purity |

| EU E316 | Europe | Safety and labeling |

| ISO 22000 | International | Factory management |

| HACCP | International | Hazard prevention |

| HALAL | Middle East / SE Asia | Religious compliance |

How Do Manufacturers Maintain Consistency in Sodium Erythorbate?

Batch-to-batch variation causes inconsistent food appearance and flavor. These surprises make it hard to maintain your recipe quality. Process control is essential for providing a uniform product every time you order.

Manufacturers maintain consistency by using automated fermentation controls and standardized raw material sourcing. Regular internal audits and the use of "retainer samples" allow quality control teams to compare new batches against previous production, ensuring uniform performance in every shipment.

Process Control and Traceability

Sodium Erythorbate is made by fermentation. This means we work with living microorganisms. If the temperature or oxygen levels change, the output changes. Modern factories in China use automated sensors. These sensors monitor the tank 24 hours a day. They adjust settings automatically. This reduces the risk of human error. By keeping the fermentation environment stable, we get the same crystalline structure in every batch. This is why our product always has the same color and dissolution speed.

Raw material sourcing is also key. We use high-quality corn glucose. If the glucose has impurities, the fermentation will be unstable. We work with the same raw material suppliers for many years. This ensures the "feed" for our microbes is always the same. I monitor these supply chains. I make sure our factories do not switch to lower-quality raw materials to save money. A professional factory also keeps a "retainer sample" from every batch for two years. If a buyer has a question, we can test the exact material again. We compare new production against these old samples. This is called "batch-to-batch verification." We also use a tracking system. Every bag has a batch number. This tells us which workers were on duty and which tank was used.

| Consistency Tool | Action | Result |

|---|---|---|

| Automated Sensors | Real-time monitoring | Stable reaction |

| Raw Material Audits | Testing glucose arrivals | Uniform fermentation |

| Retainer Samples | Storing samples (2 years) | Quality tracking |

| Batch Numbering | Full traceability | Fast problem resolution |

How Does Storage Affect Sodium Erythorbate Quality?

Poor storage turns Sodium Erythorbate yellow and reduces its antioxidant power. These changes make the product useless for your food factory. Proper handling preserves the chemical activity and saves your investment.

Storage affects Sodium Erythorbate quality through exposure to light, heat, and moisture. These factors cause oxidation and clumping. To maintain quality, store it in a cool, dry, dark place in original airtight packaging. This ensures a shelf life of up to 24 months.

Managing Environmental Sensitivity

Sodium Erythorbate is an antioxidant. Its job is to react with oxygen so your food does not have to. If the powder is exposed to air, it will start to work inside the bag. This turns the white crystals yellow. Once it turns yellow, it has lost its power. Heat speeds up this reaction. If your warehouse is too hot, the product will degrade faster. We use thick plastic liners to keep oxygen out. But the storage environment is still the buyer's responsibility. Moisture is another enemy.

Sodium Erythorbate is very soluble. If the air is humid, the powder absorbs moisture. This causes clumping. While clumping does not always ruin the chemistry, it makes the powder hard to use. You might have to break clumps by hand. This can introduce dirt or bacteria. We recommend keeping humidity below 50%. Use the "first-in, first-out" (FIFO) method to keep stock fresh. Light can also trigger the breakdown of the molecule. This is why we use opaque packaging. You should not leave bags open in bright factory rooms. Once a bag is opened, use it quickly or reseal it tightly. At FINETECH, we ensure our packaging is strong enough for long sea voyages to the Middle East or Europe.

| Condition | Effect | Prevention |

|---|---|---|

| High Humidity | Clumping / Caking | Use pallets / Dehumidifiers |

| Direct Sunlight | Yellowing | Store in dark areas |

| High Heat | Loss of power | Keep below 25°C |

| Open Bags | Oxidation | Reseal airtight |

Conclusion

Quality control for Sodium Erythorbate requires strict specs, purity testing, and proper storage. I help my clients manage these variables to ensure food safety and product stability.

-

Antioxidants prevent oxidation, preserving flavor, color, and nutritional quality in food products. ↩

-

Production costs include raw materials, processing efficiency, and additive usage; high-purity ingredients reduce overall cost. ↩

-

Heavy metal limits ensure lead, arsenic, and other toxic elements are below internationally accepted safety thresholds. ↩

-

Solubility affects how easily the additive mixes into food or beverage formulations, critical for consistent quality. ↩

-

HALAL certification verifies that products meet Islamic dietary laws, assuring buyers in specific global markets. ↩