Want smoother ice cream or thicker sauces? Curious how CMC creates better food texture? Let's quickly see how Carboxymethyl Cellulose works.

CMC boosts food texture by thickening (increasing viscosity), holding water to stop separation, improving mouthfeel, keeping mixtures stable, and controlling ice crystals for smooth frozen items.

Texture is key to enjoying food. At FINETECH, we supply CMC because it delivers consistent texture. Understanding exactly how CMC achieves this helps in choosing the right grade for the right application. Let's briefly look at the mechanics.

How does Carboxymethyl Cellulose (CMC) thicken foods?

How does CMC powder make liquids thick? What's the simple science? Let's see how it builds viscosity.

CMC thickens when its long chains hydrate and tangle in water. This network traps water, restricting its movement and increasing the liquid's resistance to flow (viscosity).

CMC's thickening is physical. When added to water, CMC chains uncoil and entangle, like long spaghetti strands. This network traps water, making the liquid thicker.

Key factors are:

- Concentration1: More CMC = more tangles = higher viscosity.

- Molecular Weight (Grade)2: Longer CMC chains (higher MW) thicken more effectively.

- Shear3: CMC solutions often thin when stirred (shear-thinning) but thicken again at rest.

Thickening Mechanism Summary:

| Step | Description | Impact on Viscosity |

|---|---|---|

| Hydration | CMC chains uncoil in water due to hydrophilic groups | Prepares chains for interaction |

| Entanglement | Long polymer chains interlock and overlap | Forms a 3D network |

| Water Immobilization | Water molecules are trapped within the network | Restricts water movement |

| Increased Resistance | Solution becomes more resistant to flow | Viscosity Increases (Thickening) |

Does Carboxymethyl Cellulose (CMC) stop water separation in food?

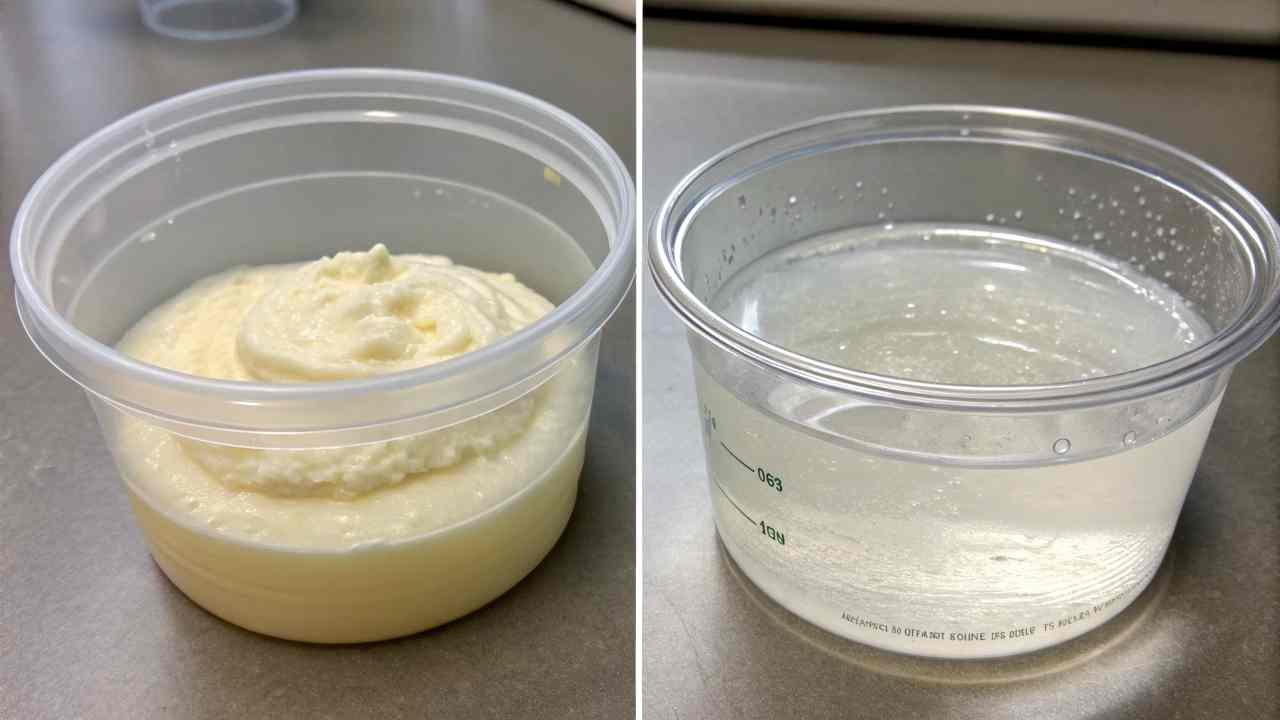

See watery stuff separate from yogurt or sauces? How does CMC prevent this? Let's see how it binds water.

Yes, CMC effectively stops water separation (syneresis). It binds water molecules and forms a stable network that holds free water, preventing it from leaking out.

Water separation4 (syneresis) makes food look bad. CMC fights this by:

- Binding Water: Its water-loving groups hold onto water molecules.

- Network Trapping: The CMC chain network physically holds water.

- Increasing Viscosity: Thicker liquid makes it harder for water to move and separate.

This keeps yogurts, sauces, and jams looking uniform and appealing longer. This quality retention is vital for FINETECH clients.

How does Carboxymethyl Cellulose (CMC) make drinks and sauces feel better?

How do diet drinks feel full or sauces coat well? Let's look at CMC's role in "mouthfeel."

CMC improves mouthfeel by increasing viscosity, giving a sense of richness or body like sugar or fat. It also creates a smooth, non-gummy texture if used right.

Mouthfeel is how food feels in your mouth. CMC helps by:

- Mimicking Fat/Sugar5: Adds body and richness in low-fat/low-sugar items (dressings, diet drinks).

- Providing Smoothness: Creates a creamy, non-gritty feel (ice cream, yogurt).

- Enhancing "Body": Makes thin liquids feel more substantial (juices, soups).

Correct CMC type and amount are key to avoid gumminess. This improves the overall eating experience.

Can Carboxymethyl Cellulose (CMC) keep food mixtures stable?

Do some dressings stay mixed without shaking? Does CMC help with this? Let's see its stabilizing power.

Yes, CMC is a great stabilizer. It stops ingredients from separating by thickening, suspending particles, and preventing settling or creaming in food mixtures.

Product stability is vital. CMC keeps mixtures uniform by:

- Increasing Viscosity6: Slows down particle movement, preventing settling (cocoa in milk) or creaming (oil in dressing).

- Particle Suspension: The CMC network traps and holds fine particles.

- Emulsion Support: Thickens the water phase around oil droplets, stopping them from merging.

- Protein Protection: Prevents clumping of milk proteins in acidic dairy products like yogurt.

This ensures products like salad dressings, chocolate milk, and sauces stay consistent.

Do heat or acid change how Carboxymethyl Cellulose (CMC) works?

Will CMC break down during cooking or in acidic foods? How does it hold up? Let's check its stability.

CMC is generally stable to heat in typical food processing. Viscosity drops when hot but recovers on cooling. It's also stable in moderately acidic foods (pH > 4), but very low pH can reduce its effect.

CMC handles common food conditions well:

- Heat: Viscosity decreases when hot but usually returns when cool. It withstands pasteurization and UHT.

- Acid (pH): Works best at neutral to slightly alkaline pH (7-9). It's stable in moderately acidic foods (pH 4-7, like tomato sauces, juices). Below pH 4, its effectiveness can decrease, and it might precipitate at very low pH (e.g., <3).

This robustness makes CMC versatile for many food applications, a key quality FINETECH ensures.

Stability Overview:

| Condition | CMC Behavior | Implication for Food |

|---|---|---|

| Heat (Typical) | Viscosity lowers (reversibly) | Good for cooked/pasteurized foods |

| Moderate Acid | Good stability | Works in juices, sauces |

| Low Acid (<4) | Reduced effect, may precipitate | Test needed for very acidic items |

Conclusion

CMC expertly enhances food texture by thickening, binding water, improving mouthfeel, and stabilizing mixtures. Its reliability under various conditions makes it a food industry staple.

-

Understanding how concentration affects CMC viscosity can help in optimizing formulations for various applications. ↩

-

Exploring the relationship between molecular weight and CMC thickening can enhance product development and performance. ↩

-

Learning about shear-thinning behavior in CMC solutions is crucial for applications in food and pharmaceuticals. ↩

-

Understanding water separation can help you appreciate how it impacts food quality and presentation. ↩

-

Explore how CMC can enhance low-fat and low-sugar foods, making them more enjoyable without compromising on taste. ↩

-

Understanding viscosity's impact on stability can enhance your product formulations and quality control. ↩