What if orange peels1 could become vitamin C? The race for efficient ascorbic acid production2 is reshaping food manufacturing—let’s explore how it works.

Ascorbic acid is primarily made via microbial fermentation of glucose or extracted from citrus waste. Synthetic methods dominate due to cost efficiency, while natural extraction appeals to eco-conscious markets requiring non-GMO certification.

From citrus scraps3 to lab-engineered microbes4, every production method has trade-offs.

Can Ascorbic Acid Be Extracted from Citrus Waste for Sustainable Production?

Throwing away orange peels? You’re discarding a goldmine of vitamin C. Sustainable extraction is rising—but does it scale?

Yes, citrus waste (peels, pulp) contains 0.5-1.2% ascorbic acid. Cold pressing and enzymatic hydrolysis can extract it, but yields are lower than synthetic methods. Most commercial operations blend waste-derived and fermented ascorbic acid.

Citrus Waste vs. Synthetic Production: A Cost-Benefit Analysis

Extraction Process:

- Cold Pressing:

- Pros: Minimal chemical use, retains natural antioxidants

- Cons: 40% lower yield than fermentation, limited to seasonal fruit waste

-

Enzymatic Hydrolysis: Enzyme Type Cost per Ton Yield Increase Certification Compatibility Optimal pH Pectinase $120 15% Organic, Halal 3.5-4.5 4-6 hours Cellulase $180 25% Non-GMO only 4.0-5.0 8-10 hours Hemicellulase $200 20% Organic, Non-GMO 5.0-6.0 6-8 hours Amylase $150 10% Halal, Kosher 5.5-6.5 3-5 hours

Economic Viability:

- Synthetic ascorbic acid: $3.50/kg

- Citrus-derived: $6.80/kg (requires premium pricing for “natural” labeling)

FINETECH’s partners in Brazil use hybrid models—fermentation for bulk supply, citrus waste extraction for EU organic clients willing to pay 2x market price.

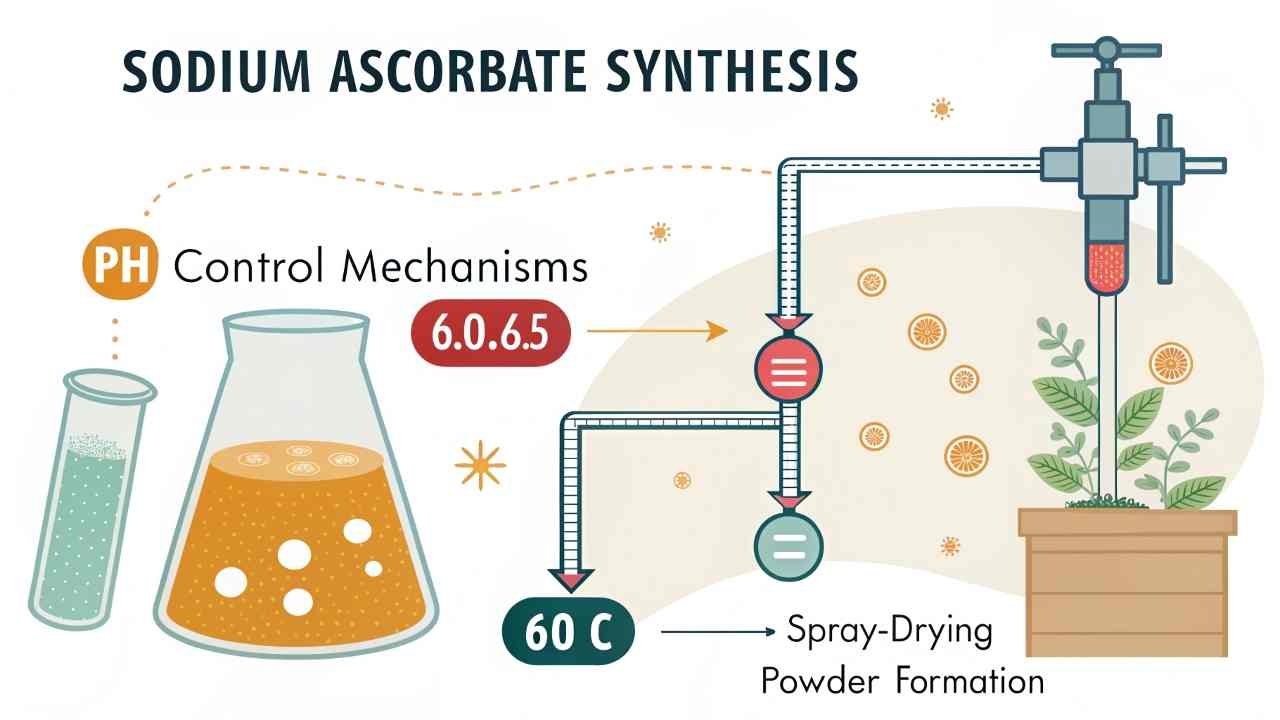

How Is Sodium Ascorbate Synthesized from Ascorbic Acid?

Neutralizing vitamin C creates a shelf-stable powerhouse—but one wrong pH shift ruins batches.

Sodium ascorbate is made by reacting ascorbic acid with sodium bicarbonate in water. The solution is spray-dried at 60°C to form powder. Critical factors: pH control (6.0-6.5) and residual sodium levels (<11%).

Industrial Synthesis Workflow

| Step | Equipment | Quality Checkpoints | Common Errors |

|---|---|---|---|

| Acid-Base Reaction | Reactor tank | pH monitoring every 5 mins | Overheating (causes oxidation) |

| Filtration | Centrifuge | Clarity testing | Incomplete neutralization |

| Drying | Spray dryer | Moisture content (<0.5%) | Temperature fluctuations |

A Malaysian client reduced batch failures by 75% after FINETECH upgraded their pH sensors and implemented real-time monitoring—saving $12,000/month in wasted raw materials.

What Technologies Prevent Oxidation in Ascorbic Acid Manufacturing?

Oxygen is vitamin C’s worst enemy. Let’s explore how factories win this chemical war.

Nitrogen blanketing, vacuum drying, and edible coatings (like ethyl cellulose) prevent oxidation. Advanced facilities use AI-driven oxygen sensors to maintain <0.1% O2 levels during processing.

Oxidation Prevention Methods Compared

| Technology | Cost per Ton | Effectiveness | Suitable For |

|---|---|---|---|

| Nitrogen Blanketing | $8 | 90% | Liquid solutions |

| Vacuum Drying | $15 | 95% | Powder production |

| Encapsulation | $22 | 98% | High-value supplements |

A Turkish juice manufacturer reduced vitamin C loss from 30% to 8% by switching to FINETECH’s vacuum-dried ascorbic acid—extending product shelf life by 4 months.

Why Is Natural Ascorbic Acid More Expensive Than Synthetic Alternatives?

“Natural” sounds wholesome—but its price tag often shocks buyers. Here’s why.

Natural ascorbic acid costs 2-3x more due to lower yields (5-7% from plants vs. 95% from fermentation), organic certification fees, and seasonal raw material shortages.

Cost Breakdown for Natural Sources

| Source | Extraction Yield | Labor Cost | Certification | Total Production Cost |

|---|---|---|---|---|

| Acerola Cherry | 6.2% | High | Organic, Halal | $9.80/kg |

| Rose Hips | 4.8% | Medium | Kosher | $11.20/kg |

| Camu Camu | 3.1% | Very High | Non-GMO | $14.50/kg |

Synthetic ascorbic acid remains at $3.50-$4.20/kg. FINETECH bridges this gap by blending natural/synthetic batches for mid-tier markets—cutting costs by 35% while keeping “natural” claims.

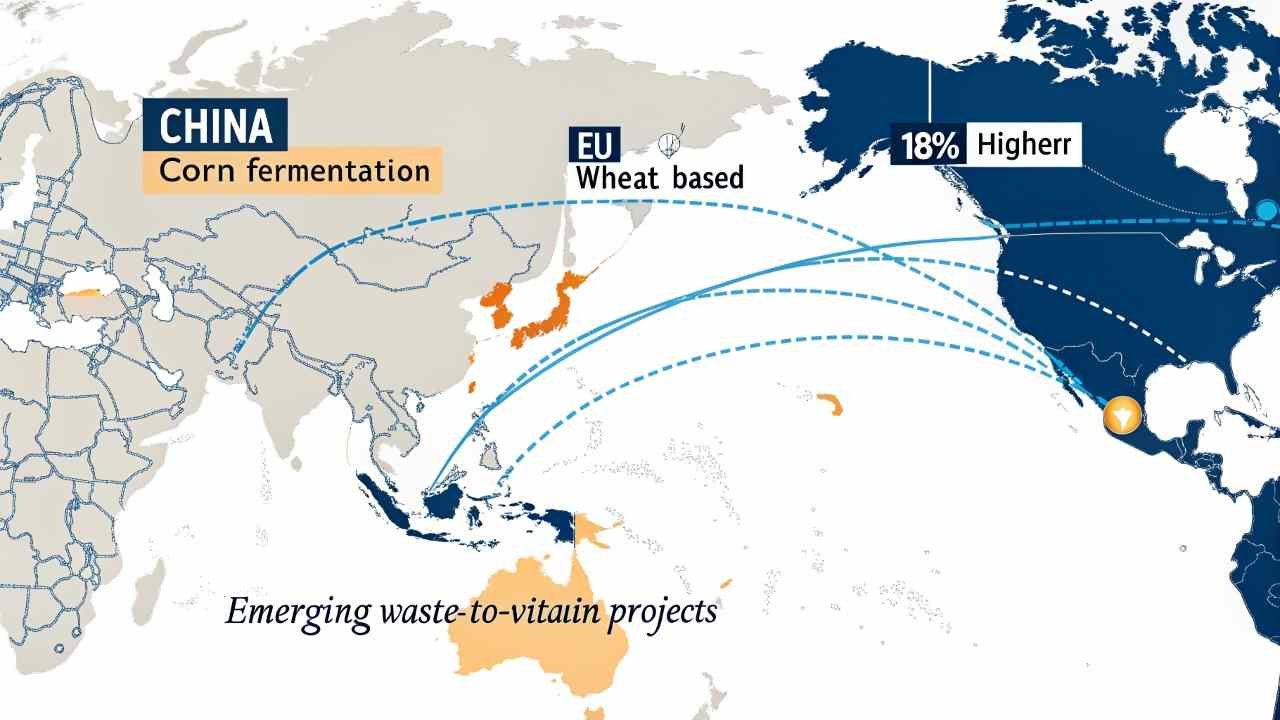

What Are the Cheapest Sources of Ascorbic Acid for Industrial Use?

Buying bulk vitamin C? Your supplier’s glucose source5 matters more than you think.

Chinese corn-derived glucose via microbial fermentation is the cheapest ($3.20/kg). Wheat-based (EU) costs 18% more. Waste-to-vitamin projects show promise but currently add 10-15% to pricing.

Global Price Matrix (1000kg+ Orders)

| Base Material | Region | Price/kg | Lead Time | Certifications Included |

|---|---|---|---|---|

| Corn Glucose | China | $3.20 | 2 weeks | Halal, ISO22000 |

| Wheat Glucose | Germany | $3.78 | 6 weeks | Kosher, Organic |

| Cassava | Thailand | $3.45 | 3 weeks | Non-GMO, BRCGS |

Conclusion

Master ascorbic acid production methods—from citrus upcycling to bulk fermentation—to balance cost, quality, and market demands effectively. Smart sourcing starts with understanding the chemistry behind the powder.

-

Explore the potential uses of orange peels in food production and their nutritional benefits. ↩

-

Discover innovative techniques and advancements in ascorbic acid production that are transforming the food industry. ↩

-

Exploring this resource will reveal innovative uses of citrus scraps, enhancing sustainability in production methods. ↩

-

This link will provide insights into the role of lab-engineered microbes, showcasing their potential in modern production techniques. ↩

-

Understanding the impact of glucose sources on vitamin C quality can guide you in choosing the right supplier for your needs. ↩