Ever wonder how a microbe turns corn syrup into 2 million tons of citric acid yearly? From fermentation tanks1 to your soda can—let’s decode this industrial alchemy.

Citric acid is made via Aspergillus niger fermentation of sugars (corn/beet), then purified into powder/crystals. It’s GRAS-approved in foods (<1%) but requires PPE handling in concentrated (>50%) industrial forms.

Understanding production methods and safety protocols helps buyers avoid quality issues. Here’s your technical guide to sourcing citric acid smartly.

How Is Citric Acid Produced Industrially?

Forget squeezing lemons—modern citric acid comes from genetically tweaked fungi2 eating cheap sugars at scale.

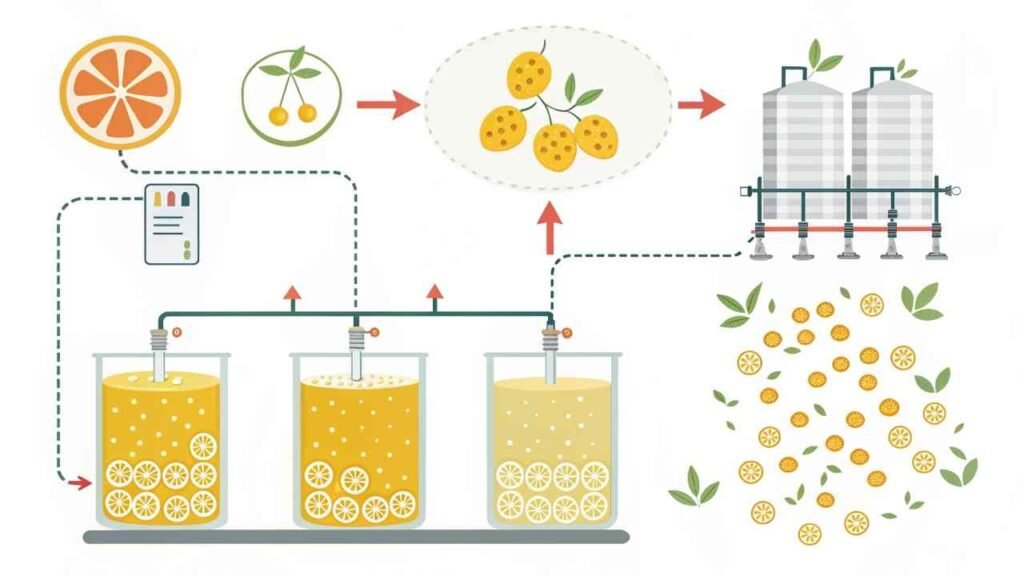

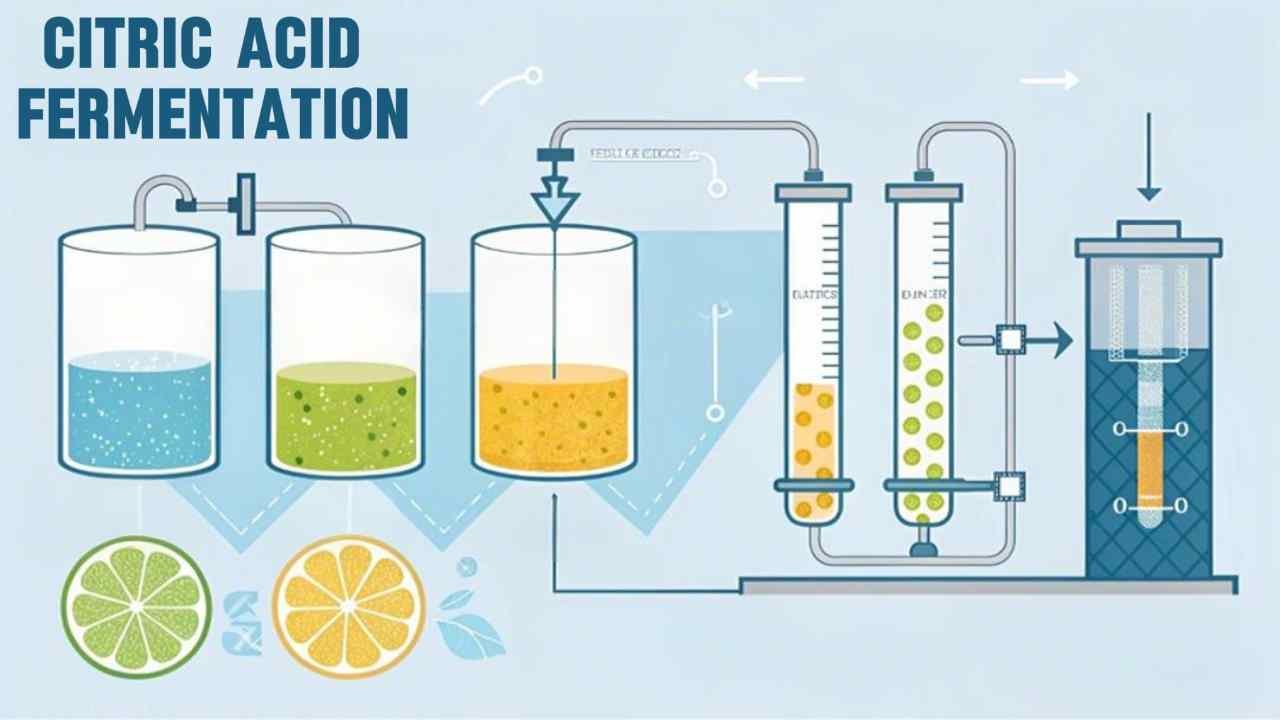

95% of citric acid is made by fermenting glucose syrup with Aspergillus niger for 5-10 days. The liquid is filtered, precipitated with lime, and purified to 99.5% crystals.

Production Step Breakdown

| Stage | Duration | Key Parameters | Output Quality Factors |

|---|---|---|---|

| Fermentation | 5-7 days | pH 3.0-3.5, 30-35°C | Sugar-to-acid conversion rate |

| Filtration | 8-12 hrs | Diatomaceous earth grade | Clarity (NTU <5) |

| Precipitation | 4-6 hrs | Calcium hydroxide purity | Citrate crystal size |

| Acidification | 2-3 hrs | Sulfuric acid concentration | Residual sulfate levels |

FINETECH’s partner reduced energy costs by 18% using AI-controlled fermentation pH systems in 2023.

Is Citric Acid Safe to Eat or Not?

Your body makes citric acid daily—but industrial-grade powder3 has different rules than natural lemon juice.

Food-grade citric acid (E330) is safe at <1% in foods. Avoid inhaling powder or using >10% solutions on skin. Industrial grades may contain heavy metals requiring SDS checks.

Safety Standards Comparison

| Grade | Purity | Allowable Impurities | Max Daily Intake |

|---|---|---|---|

| Food (FCC) | 99.5%+ | Lead <1ppm, Sulfate <0.05% | No limit |

| Pharmaceutical (USP) | 99.9%+ | Arsenic <3ppm, Oxalate <0.1% | 500mg/kg body weight |

| Industrial | 98% | Heavy metals <50ppm | Not for consumption |

EU jam recalls in 2022 proved this: 3 factories used industrial-grade citric acid with 23ppm lead—exceeding limits by 2300%.

What Is the Difference Between Citric Acid and Sodium Citrate?

Swap one for the other, and your product’s pH could skyrocket—or crash. Know their chemical personalities4.

Citric acid (C₆H₈O₇) is acidic (pH 2-3). Sodium citrate (Na₃C₆H₅O₇) is alkaline (pH 7-9). Use citric acid for sourness/preservation, sodium citrate for buffering/emulsifying.

Functional Differences

| Property | Citric Acid | Sodium Citrate |

|---|---|---|

| pH (1% solution) | 2.2 | 7.5 |

| Solubility | 59g/100ml (20°C) | 72g/100ml (20°C) |

| Common Uses | Beverage acidulant | Cheese emulsifier |

| Safety Handling | Corrosive at >50% | Mild irritant |

A Dubai dairy company fixed texture issues in halal cheese by switching from citric acid to FINETECH’s sodium citrate—raising pH from 4.8 to 6.2.

Does Citric Acid Expire or Lose Potency?

Old citric acid won’t poison you—but it might fail to clean your kettle or preserve your jam.

Dry citric acid lasts 3-5 years if stored <25°C/60% humidity. Solutions degrade faster: 10% loss/year at 25°C. Clumping signals moisture absorption, not expiration.

Degradation Factors

| Storage Condition | Annual Potency Loss | Physical Changes |

|---|---|---|

| 25°C, dry | 0.5% | None |

| 30°C, 70% humidity | 8% | Clumping, discoloration |

| 40°C, sealed | 3% | Mild yellowing |

Is Concentrated Citric Acid Hazardous in Manufacturing?

50% citric acid solutions5 dissolve scale—and skin. Proper handling prevents costly accidents.

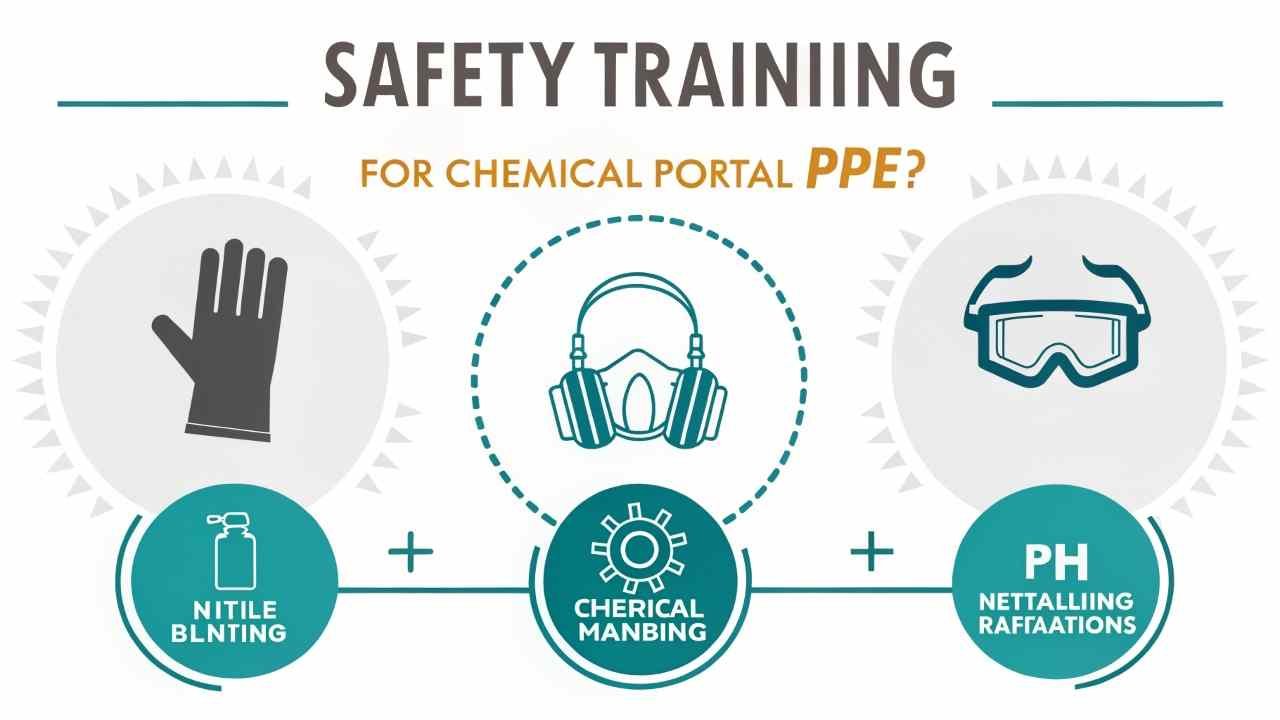

Concentrated citric acid (>30%) causes skin/eye burns. Use PPE: nitrile gloves, goggles, pH-neutralizing stations. Ventilate areas to avoid powder inhalation (TLV 2mg/m³).

Hazard Control Measures

| Concentration | Risk Level | Required PPE | First Aid Response |

|---|---|---|---|

| <10% | Low | Gloves | Rinse with water |

| 10-30% | Moderate | Gloves + goggles | 15-min flush |

| >30% | High | Full-face shield + apron | Medical evaluation |

A 2023 Saudi factory incident proved this: workers without goggles suffered eye burns from 40% solution splashes—costing $120K in fines and downtime.

Conclusion

Master citric acid’s production methods, storage needs, and safety protocols to ensure quality and compliance—partner with suppliers who test every batch.

-

Learn about the technology behind fermentation tanks and their crucial role in producing citric acid. ↩

-

Explore this link to understand how genetically tweaked fungi are revolutionizing industries, including food production and biotechnology. ↩

-

Understanding the regulations for industrial-grade powder can help ensure compliance and safety in its use. ↩

-

Discover how chemical personalities affect product interactions and performance. This resource will deepen your understanding of formulation chemistry. ↩

-

Explore how citric acid solutions can effectively clean and dissolve scale, making them a valuable resource for maintenance. ↩