Frustrated with clumpy sauces or inconsistent textures when using xanthan gum? This powerful thickener needs proper handling to unlock its full potential in your food production.

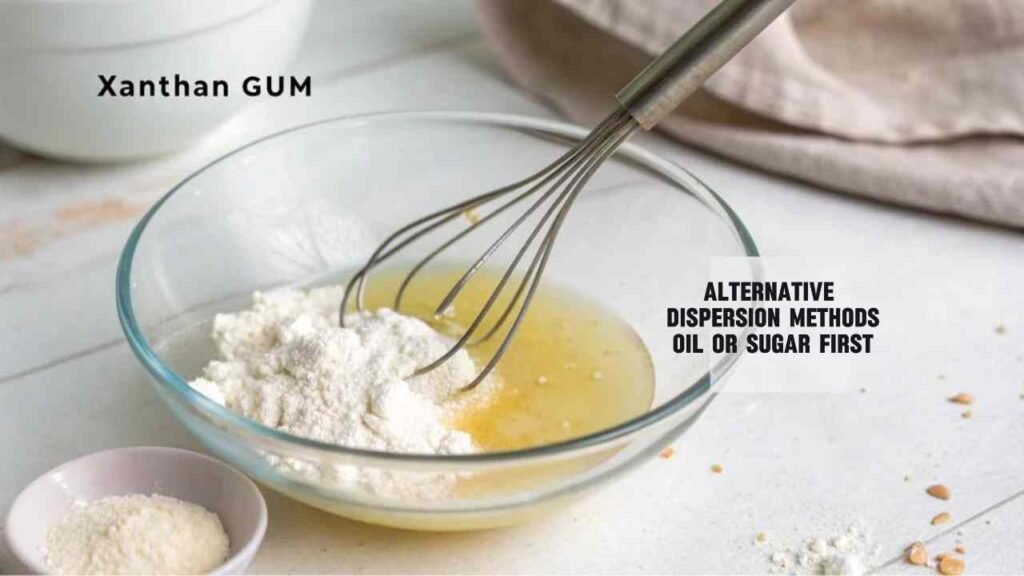

To use xanthan gum effectively, ensure it's fully dispersed before hydrating, often by blending with oil or sugar first, or using high-shear mixing. Use precise measurements, as only small amounts are needed.

Xanthan gum is an excellent ingredient. When used correctly, it ensures a flawless product and prevents potential issues. For buyers who prioritize quality, mastering its application is key to avoiding production problems. Let’s explore the best practices for incorporating xanthan gum and other relevant considerations.

What Ingredients Can Replace Xanthan Gum in Recipes?

Out of xanthan gum? Don’t panic—these swaps save recipes while keeping textures intact. Choose based on dietary needs and application.

Common xanthan gum substitutes include guar gum, psyllium husk, chia/flax seeds, and cornstarch. The best choice depends on whether you need cold thickening, heat stability, or specific textures.

Comparing Common Replacements

Swapping thickeners requires understanding their different properties. Consistency is crucial in food manufacturing, so choosing wisely matters.

| Substitute | Typical Ratio (vs. Xanthan) | Needs Heat? | Key Feature(s) | Best For |

|---|---|---|---|---|

| Guar Gum | ~1:1 | No | Good cold thickener, Cost-effective | Dressings, Ice Cream, Cold Sauces |

| Psyllium Husk | ~2:1 + More Liquid | No | Strong binder, High fiber | GF Bread |

| Chia/Flax Gel | Variable | No | Gel binder, Adds nutrition | Vegan/GF Baking, Smoothies |

| Cornstarch | High (~4-8:1) | Yes | Starchy thickener, Opaque | Cooked Sauces, Gravies, Pie Fillings |

Consider your recipe's needs: hot/cold prep, desired texture, pH, cost. At FINETECH, we supply quality xanthan but can discuss alternatives if your formulation requires them.

How to Add Xanthan Gum to Hot Liquids Without Clumping?

Getting clumps when adding xanthan gum directly to hot soups or sauces? Heat makes proper dispersion even more critical and difficult. Avoid lumps with the right technique.

Prevent clumps in hot liquids by dispersing xanthan gum first in oil or a bit of cold liquid, or use an immersion blender for direct, high-shear mixing into the hot liquid.

Why Heat Increases Clumping

Xanthan gum hydrates and thickens extremely fast. Heat speeds this up dramatically. Adding powder straight to hot liquid causes instant surface gelling1, trapping dry powder inside and forming stubborn lumps that are hard to break down.

Effective methods for hot liquids:

- Oil Slurry: If the recipe uses oil, mix xanthan gum into a small amount of cool oil first until smooth. Whisk this slurry rapidly into the hot liquid. The oil barrier allows dispersion before hydration.

- Cold Liquid Slurry: Mix xanthan gum thoroughly into a small amount of cold liquid (water, broth, etc.) until smooth. Slowly whisk this cold slurry into the main hot liquid (like tempering).

- Immersion Blender (High Shear): The most direct method. Put an immersion blender into the hot liquid, turn it on, and slowly sprinkle the xanthan gum into the vortex. The high speed disperses it instantly.

Direct whisking without pre-dispersion is very likely to cause clumps in hot liquids. Industrial processes typically use high-shear mixing2 for incorporating gums into hot batches.

| Technique | How it Prevents Clumps | Effectiveness (Hot) | Key Point |

|---|---|---|---|

| Oil Slurry | Oil coating delays hydration | Good | Requires oil in recipe |

| Cold Liquid Slurry | Pre-disperse in cold liquid | Good | Extra step, ensures smooth start |

| Immersion Blender | High shear disperses instantly | Excellent | Fast, direct, needs blender |

| Direct Whisking | Relies on manual mixing | Poor | High risk of clumps |

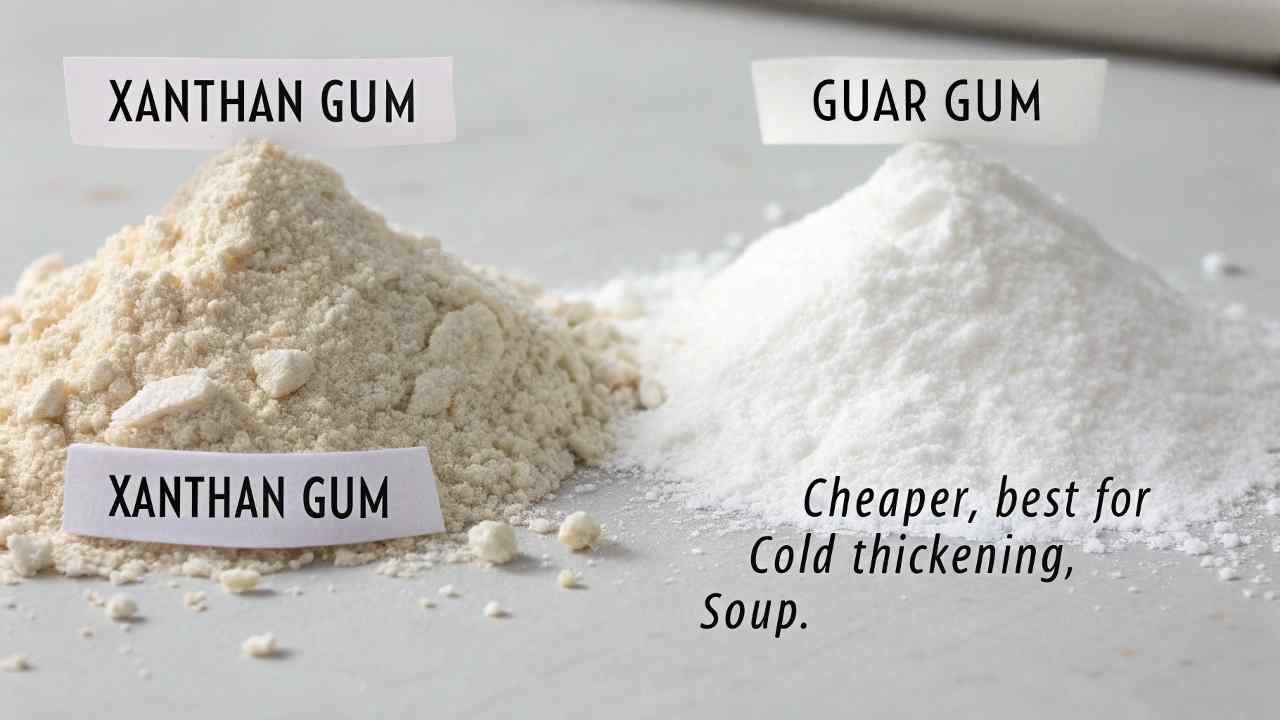

Which Is Better: Xanthan Gum or Guar Gum in Food?

Deciding between xanthan gum and guar gum? Both thicken well, but key differences in stability, texture, and cost make one better suited for certain applications.

Neither is always 'better'. Xanthan offers superior heat/pH stability and smoother texture. Guar is often cheaper and excellent for cold thickening but less stable and can be slightly slimy.

Xanthan vs. Guar Head-to-Head

Understanding the differences helps choose the right gum for your product and budget.

| Feature | Xanthan Gum | Guar Gum | Advantage / Key Use |

|---|---|---|---|

| Heat/pH Stable | Excellent | Fair | Xanthan (for dressings, hot sauces) |

| Texture | Smooth, Clean | Thick (can be slightly slimy) | Xanthan (for smooth mouthfeel) |

| Cold Use | Good | Excellent | Guar (easy hydration, often cheaper) |

| Cost | Generally Higher | Generally Lower (variable) | Guar (often, check price/use level) |

Sometimes a blend of both is used to balance properties and cost3. As your supplier, FINETECH can provide competitive pricing and guidance on selection.

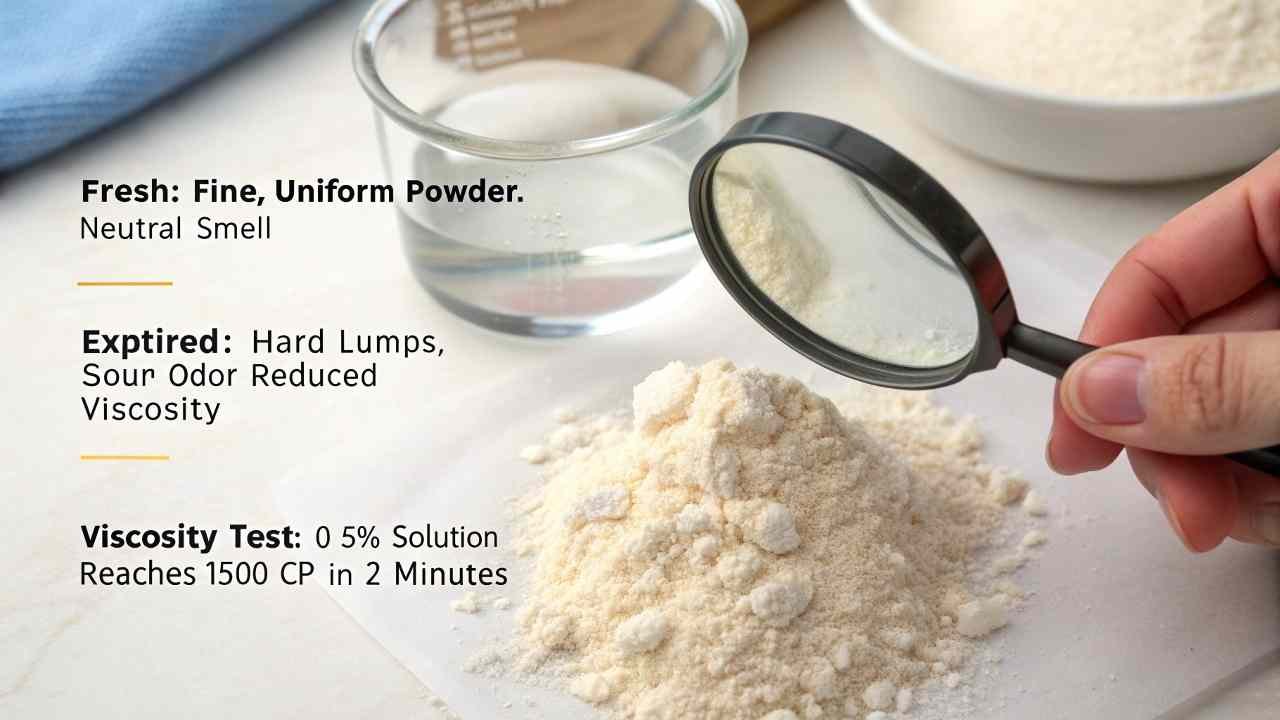

How to Determine If Xanthan Gum Has Expired or Degraded?

Concerned your stored xanthan gum might have lost its effectiveness? Using degraded gum can ruin batches, impacting consistency and cost. Check its quality before use.

Expired xanthan forms hard lumps, loses viscosity (30%+ drop), or develops sour odor. Test by mixing 0.5% in water—fresh gum reaches 1500 cP in 2 minutes.

Identifying Poor Quality Gum

Xanthan gum is stable if stored well, but it can degrade, mainly losing thickening power4.

- Expiration Date: First check. Using expired ingredients is risky for product consistency and compliance.

- Visual Check: Look for hard clumps (moisture damage), yellowing/browning (degradation), or any foreign matter. Good gum is a white/cream, free-flowing powder.

- Smell Check: Should be odorless. Musty or sour smells indicate spoilage.

- Performance Test: The best check. Mix a standard solution (e.g., 1% in water) and compare its thickness (viscosity) to a known good sample. A noticeable decrease means it has degraded.

Proper Storage: Keep xanthan gum cool, dry, and tightly sealed to prevent moisture absorption and extend shelf life. Using degraded gum leads to inconsistent products. At FINETECH, we ensure fresh stock with good shelf life.

| Check | Good Quality | Bad Quality / Degraded | Action |

|---|---|---|---|

| Date | Within Expiry | Past Expiry | Check performance/Discard |

| Appearance | White, Free-flowing | Clumped, Discolored | Discard |

| Odor | Odorless | Musty, Sour, Off-odor | Discard |

| Performance | Thickens effectively | Significantly less viscous | Discard |

What Are the Pros and Cons of Using Xanthan Gum in Cooking?

Deciding whether to use xanthan gum? Understanding its advantages and disadvantages helps determine if it's the right choice for your specific culinary or production needs.

Pros: Xanthan gum is a highly effective thickener/stabilizer, versatile (hot/cold, wide pH), great for gluten-free, and needed only in small amounts. Cons: Can clump if added improperly, potential digestive effects for some, rare allergy concerns, cost.

Weighing the Benefits and Drawbacks

Xanthan gum offers significant advantages but also has aspects to manage.

| Aspect | Pros | Cons |

|---|---|---|

| Function | Powerful thickener/stabilizer, Good suspension | Can be gummy if overused |

| Versatility | Works hot/cold, wide pH, freeze-thaw stable | - |

| Use | Essential for GF baking, Low dosage needed | Prone to clumping if added incorrectly |

| Sensory | Smooth texture, clean mouthfeel | Potential slight digestive issues (high dose), Rare allergy risk |

| Cost | Effective at low levels | Can be pricier than basic starches or guar gum |

For most applications, the pros heavily outweigh the cons, especially when proper usage techniques are followed. Its reliability and versatility5 make it a staple for many food manufacturers we supply at FINETECH.

Conclusion

Master xanthan gum’s unique properties and alternatives to optimize food textures—source from suppliers who test batch consistency and offer technical support.

-

Learn about surface gelling to improve your cooking techniques and avoid common pitfalls when using thickening agents. ↩

-

Understanding high-shear mixing can enhance your knowledge of industrial applications and improve process efficiency. ↩

-

Exploring strategies to balance properties and cost can enhance your efficiency and profitability in manufacturing processes. ↩

-

Learn about the factors influencing thickening power to improve your cooking techniques and ingredient choices. ↩

-

Exploring versatility in food manufacturing can provide insights into innovation and product development strategies. ↩