Have you ever received a shipment with torn, wet bags? This packaging failure leads to product loss, contamination, and costly disruptions in your warehouse.

The common export packaging for Potassium Sorbate is a 25 kg multi-wall kraft paper bag with a heat-sealed inner polyethylene (PE) liner. This system is designed to provide robust protection against physical damage and, most importantly, moisture during international transit.

After we have guaranteed the quality of the product inside the bag, my next most important job is to guarantee the quality of the bag itself. The process of goods transportation is long and challenging. The packaging is not just a container; it is a technical system engineered to protect your investment. Let's look at the industry standards and why they are so important.

What Bag Types Are Used for Potassium Sorbate Export?

Are you concerned that the packaging for your valuable ingredient might not be strong enough? A flimsy bag can easily tear, causing product loss and contamination risks.

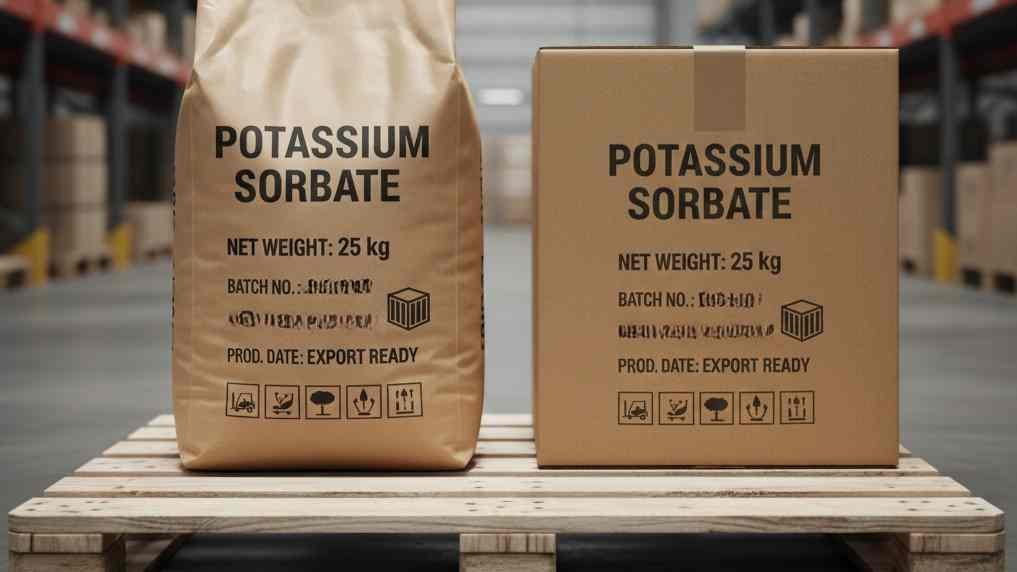

The global industry standard for Potassium Sorbate export is the multi-wall kraft paper bag with a separate inner plastic liner. Rigid cartons or fiber drums are also used, especially for the granular form, but bags are the most common for powder.

The two standard packaging options are designed for protection and efficiency. The multi-wall kraft paper bag1 is the most common for powder. Its layered construction is strong, tear-resistant, and cost-effective. For the granular form, cardboard cartons2 are also widely used due to their excellent stacking strength. For most large FCL (Full Container Load) shipments, the multi-wall bag offers the perfect combination of protection and value.

Packaging Format Comparison:

| Feature | Multi-Wall Kraft Paper Bags | Cardboard Cartons / Fiber Drums |

|---|---|---|

| Common Form | Powder, fine granular | Granular, spherical |

| Physical Protection | Good, tear-resistant | Excellent, crush-resistant |

| Cost | More Cost-Effective | Higher |

| Space Efficiency (FCL) | Excellent | Good |

How Does Packaging Protect Potassium Sorbate Quality?

You approved a perfect sample. But the product that arrives is yellowed, clumpy, or contaminated. The long journey has ruined it.

Packaging is an active quality protection system. It defends Potassium Sorbate against its three main enemies during transit: moisture which causes caking, physical impacts which cause loss, and environmental factors like light and contamination which cause degradation.

Professional packaging provides three layers of defense. First, it offers a moisture barrier3 to prevent the powder from absorbing humidity and forming hard clumps (caking). Second, its strong construction provides physical protection4 against punctures and damage during handling. Third, the opaque and sealed layers act as a shield against light and contamination, ensuring the product arrives in a pure, pristine condition, just as it left the factory.

Packaging's Protective Functions:

| Threat | Packaging Solution | Benefit to Buyer |

|---|---|---|

| Moisture | Heat-Sealed Inner PE Liner | Prevents caking, ensures a free-flowing product. |

| Impact / Punctures | Multi-Wall Kraft Paper Bag, Palletizing | Prevents product loss from torn bags. |

| Light (UV) | Opaque Paper or Carton Layers | Protects against yellowing and degradation. |

| Contamination | Sealed Inner Liner | Guarantees product purity upon arrival. |

What Net Weights Are Standard for Potassium Sorbate Bags?

You need to plan your inventory and production batches precisely. But if your incoming bags have inconsistent or non-standard weights, it creates chaos.

The global industry standard net weight for Potassium Sorbate bags and cartons is 25 kilograms. This standard is optimized for safe manual handling, efficient pallet stacking, and maximizing the payload of a standard 20-foot shipping container.

The 25 kg net weight is a global standard for a reason. It is safe for manual handling and creates perfect efficiency in logistics. We stack 40 bags on a pallet to make a 1-ton unit. We then load 20 pallets into a container for a total net weight of 20 metric tons. This standardization makes logistics completely predictable, which is essential for professional buyers.

Standard FCL (20-foot Container) Configuration:

| Unit | Specification | Total |

|---|---|---|

| Bag | 25 kg Net Weight | 25 kg |

| Pallet | 40 Bags per Pallet | 1,000 kg (1 Metric Ton) Net Weight |

| Container | 20 Pallets per Container | 20,000 kg (20 Metric Tons) Net Weight |

How Can Packaging Reduce Potassium Sorbate Moisture Risk?

You open a bag and find a solid brick instead of a powder. The product is ruined. The cause is almost always a failure of the packaging's moisture defense.

Packaging's primary defense against moisture is the heat-sealed inner polyethylene (PE) liner. This food-grade plastic bag is sealed airtight, creating a robust, impermeable barrier that prevents the hygroscopic Potassium Sorbate powder from absorbing humidity.

The most critical feature for preventing moisture damage is the two-layer bag system. The tough outer paper bag provides physical strength. The real hero is the inner polyethylene (PE) liner. We use a machine to heat-seal5 this inner bag, creating a completely airtight barrier. This seal is what locks out the humid ocean air and guarantees that your product will arrive as a perfect, free-flowing powder, ready for use.

The Layers of Moisture Defense:

| Layer | Component | Function |

|---|---|---|

| Primary Defense | Heat-Sealed Inner PE Liner | Creates an airtight, impermeable barrier. |

| Secondary Defense | Multi-Wall Kraft Paper Bag | Provides physical protection for the inner liner. |

| Tertiary Defense | Plastic Stretch-Wrap on the Pallet | Adds an extra layer of protection. |

What Packaging Details Do Importers Check for Potassium Sorbate?

Your 20-ton shipment has just arrived. What should you be looking for? Accepting a shipment with hidden packaging problems can lead to major issues.

Upon receiving a Potassium Sorbate shipment, importers must check three key details: the physical integrity of the packaging (no damage), the clarity and accuracy of the labels on every bag, and, most importantly, that the batch number on the bags matches the shipping documents and COA.

A professional receiving process is your final quality check. First, do a visual inspection6 for any physical damage before unloading. Take photos of any problems. Second, check the labels to ensure they are clear, professional, and contain all the required information. Third, and most importantly, perform the golden rule of receiving: match the batch number. The batch number on the bags must match the number on your Certificate of Analysis (COA) and Packing List to ensure full traceability.

Importer's Receiving Checklist:

| Check | Action | Purpose |

|---|---|---|

| 1. Physical Integrity | Inspect pallets and bags for any damage before unloading. | To identify and document any in-transit damage for claims. |

| 2. Label Accuracy | Check that labels are clear, professional, and contain all key info. | To ensure professional handling and clear identification. |

| 3. Batch Number Match | Confirm batch number on bags matches COA and packing list. | To guarantee product traceability and quality control. |

Conclusion

Export packaging for Potassium Sorbate is a technical system. The standard 25 kg, double-layered bag ensures your product arrives safely, ready for use, with full traceability.

-

Explore this link to understand why multi-wall kraft paper bags are ideal for protecting and efficiently packaging powders. ↩

-

Discover the advantages of cardboard cartons in packaging, especially for their stacking strength and efficiency. ↩

-

Understanding moisture barriers can help you choose the right packaging to protect your products from humidity. ↩

-

Exploring physical protection in packaging will enhance your knowledge of how to safeguard products during transport. ↩

-

Learn about heat-seal technology and its crucial role in creating airtight seals for moisture protection. ↩

-

Understanding the role of visual inspection can enhance your quality control processes and prevent costly errors. ↩