Are you worried about your high-value Vitamin A losing its potency during shipment? The wrong packaging can degrade your product before it even reaches you. It is a costly risk.

The best packaging for Vitamin A exports is a multi-layer barrier system. For bulk, this is typically a 20kg carton containing a heat-sealed, nitrogen-flushed aluminum foil bag. This robust system protects the sensitive vitamin from oxygen, light, and moisture.

For a high-value item like Vitamin A, the packaging is a high-tech life support system. A serious buyer knows that the quality he receives is a direct result of the quality of the packaging the product traveled in. Let's look at why this is so critical.

Why is Vitamin A packaging important?

Do you think the packaging is just for shipping? For a sensitive product like Vitamin A, the box and bag are an essential part of the product's quality and stability.

Packaging is critically important because Vitamin A is an extremely unstable molecule. It is highly sensitive to degradation from oxygen, light, and heat. The packaging acts as an essential barrier, preserving the vitamin's chemical integrity and potency.

Vitamin A is a fragile molecule. Its value is easily destroyed by its three main enemies: oxygen1, which breaks down its chemical structure (oxidation); light, which speeds up this breakdown; and heat, which also accelerates the process. The sole purpose of the specialized packaging2 is to create a fortress that keeps these three enemies out, preserving the vitamin's potency from the factory to your warehouse.

Threats to Vitamin A Stability:

| Threat | Effect on Vitamin A Molecule | Result for the Buyer |

|---|---|---|

| Oxygen | Oxidation (breaks chemical bonds) | Loss of potency, reduced biological value. |

| Light (UV) | Accelerates oxidation | Faster degradation and potency loss. |

| Heat | Accelerates oxidation | Faster degradation and potency loss. |

What types of packaging are used for Vitamin A?

You have seen Vitamin A in cartons, drums, and different bags. It can be confusing. What is the industry standard, and why is it designed that way?

The standard export packaging for Vitamin A powder is a 20kg or 25kg multi-wall cardboard carton. Critically, inside the carton, the vitamin is contained within a heat-sealed, multi-layer aluminum foil bag that has been flushed with nitrogen.

The standard packaging is a two-part system. The outer carton3 is the physical armor, a strong cardboard box designed to be stacked efficiently on a pallet, protecting the contents from being crushed. The inner fortress is the high-tech, multi-layer aluminum foil bag4. This bag is the critical barrier that blocks out oxygen, moisture, and light, creating a safe environment for the sensitive vitamin inside.

Packaging Component Breakdown:

| Component | Material | Primary Function |

|---|---|---|

| Outer Container | Corrugated Cardboard Carton | Physical protection, stackability, logistics efficiency. |

| Inner Bag - Key Barrier | Aluminum Foil Composite | Blocks oxygen, moisture, and light. |

How does packaging affect Vitamin A shelf life?

You see a 24-month shelf life on the certificate. How is that possible for such an unstable product? The secret lies in creating an oxygen-free environment.

Packaging is the single most important factor for shelf life. The use of a nitrogen-flushed, sealed aluminum bag creates an inert, oxygen-free atmosphere. This effectively stops the oxidation process, preserving Vitamin A's potency for its full 24-month shelf life.

The 24-month shelf life is achieved through a critical process called nitrogen flushing5. Before the aluminum bag is sealed, the oxygen-rich air inside is flushed out and replaced with pure, inert nitrogen gas. Since nitrogen does not react with Vitamin A, this creates an oxygen-free environment. This effectively "pauses" the degradation process, locking in the vitamin's potency for two years or more. It is the key piece of technology that guarantees the product's quality.

Packaging Atmosphere and Potency Retention (Hypothetical):

| Packaging Method | Atmosphere Inside Bag | Estimated Potency after 12 Months |

|---|---|---|

| Sealed Aluminum Bag (No Flush) | Trapped Oxygen | 80-90% |

| Nitrogen-Flushed Aluminum Bag (Standard) | Inert (Nitrogen) | > 98% |

What rules apply to Vitamin A export packaging?

Is your packaging compliant with international law? One small mistake on a label can cause customs to hold your shipment.

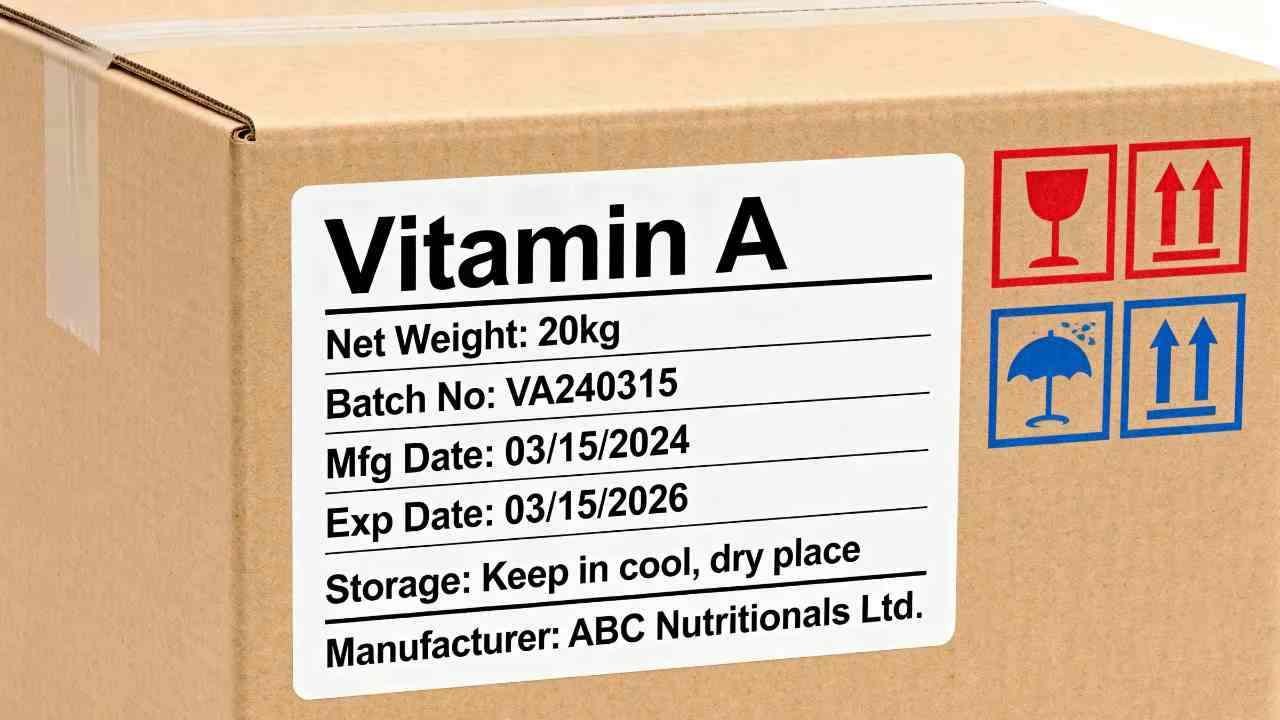

Export packaging must comply with international food safety and transport regulations. The inner packaging must be made of food-grade materials, and the outer carton must be clearly and accurately labeled with the product name, net weight, batch number, dates, and origin.

The rules for export packaging are strict. First, the inner bag must be certified food-grade to ensure no harmful chemicals can touch the product. Second, the outer label is a legal document and must be perfect. It needs to clearly show the correct product name, net weight, batch number, manufacturing and expiry dates, and storage conditions. An error on this label is one of the most common and avoidable reasons for customs delays.

Export Packaging Compliance Checklist:

| Compliance Area | Requirement | Why it's critical |

|---|---|---|

| Material Safety | Inner bag must be certified food-grade. | Ensures product safety and prevents contamination. |

| Labeling: Traceability | Batch number, production/expiry dates. | Essential for food safety and inventory management. |

How can bulk Vitamin A packaging save costs?

Does buying in bulk really save on packaging? You might be surprised how much freight efficiency and material choices add up.

Bulk packaging (like 20kg cartons) saves significant costs by maximizing freight efficiency through Full Container Load (FCL) shipments. It also reduces the per-kilogram cost of packaging materials and administrative overhead compared to shipping many smaller units.

Bulk packaging saves money in two main ways. First, and most importantly, it allows for Full Container Load (FCL) shipping. The square cartons are designed to be stacked perfectly onto pallets, maximizing the weight in a shipping container. This drastically reduces your per-kilogram freight cost compared to smaller shipments. Second, the cost of the packaging materials and labor is much lower per kilogram for a single 20kg carton than it would be for twenty 1kg packages.

Cost Efficiency: Small vs. Bulk Packaging:

| Aspect | Small Packs (e.g., 1kg Tubs) | Bulk Packs (20kg Cartons) |

|---|---|---|

| Packaging Cost / kg | High | Low |

| Freight Efficiency | Low | Highest (with FCL) |

| Overall Landed Cost / kg | High | Lowest |

Conclusion

The right packaging for Vitamin A is a critical system that preserves quality, ensures safety, meets regulations, and ultimately saves you money. It is a vital part of your investment.

-

Understanding how oxygen affects Vitamin A can help you better preserve its potency in your products. ↩

-

Exploring effective packaging solutions can enhance the shelf life and effectiveness of Vitamin A in your products. ↩

-

Understanding the role of an outer carton can enhance your knowledge of packaging efficiency and protection. ↩

-

Exploring the benefits of aluminum foil bags reveals their importance in preserving product quality and extending shelf life. ↩

-

Understanding nitrogen flushing can reveal how this technology enhances product shelf life and maintains nutrient integrity. ↩