Is your production line about to stop? Anxiously waiting for a delayed ingredient shipment? This stress can cripple your operations and damage your bottom line.

On-time delivery of Vitamin A is critically important because delays directly cause production shutdowns, leading to significant financial losses. It also damages a company's reputation by causing them to miss their own customer delivery commitments, breaking the supply chain's trust.

Delivery is one of the biggest pain points for my clients. A delay is a critical failure with a domino effect across their business. "Top quality" is meaningless if the product does not arrive when needed. At FINETECH, on-time delivery is a core part of our quality promise.

What happens if Vitamin A is delayed?

You have a production schedule planned to the hour. But your key ingredient is stuck in transit. What is the real cost of this delay?

If Vitamin A is delayed, the immediate result is a halt in production. This creates a chain reaction of negative consequences, including idle labor costs, missed customer deadlines, lost sales, and severe damage to your company's reputation for reliability.

The costs of a late shipment are severe. The most immediate impact is a production shutdown1. In a lean manufacturing environment, a delay of even a few days means the factory runs out of a critical ingredient, leading to direct financial losses from idle machinery and labor. The second impact is reputational damage2. When your production stops, you cannot deliver to your own customers. This lost trust can be even more costly than the production downtime, as a customer you lose may never come back.

The Costs of a Late Shipment:

| Cost Type | Specific Example | Business Impact |

|---|---|---|

| Direct Costs | Idle machinery, worker salaries during downtime. | Immediate and measurable financial loss. |

| Reputational Costs | Seen as an unreliable partner by your customers. | Damage to brand image, loss of future business. |

How do suppliers plan Vitamin A delivery?

You place an order and are given a delivery date. How does a reliable supplier make sure they hit that date? It is not luck; it is a structured planning process.

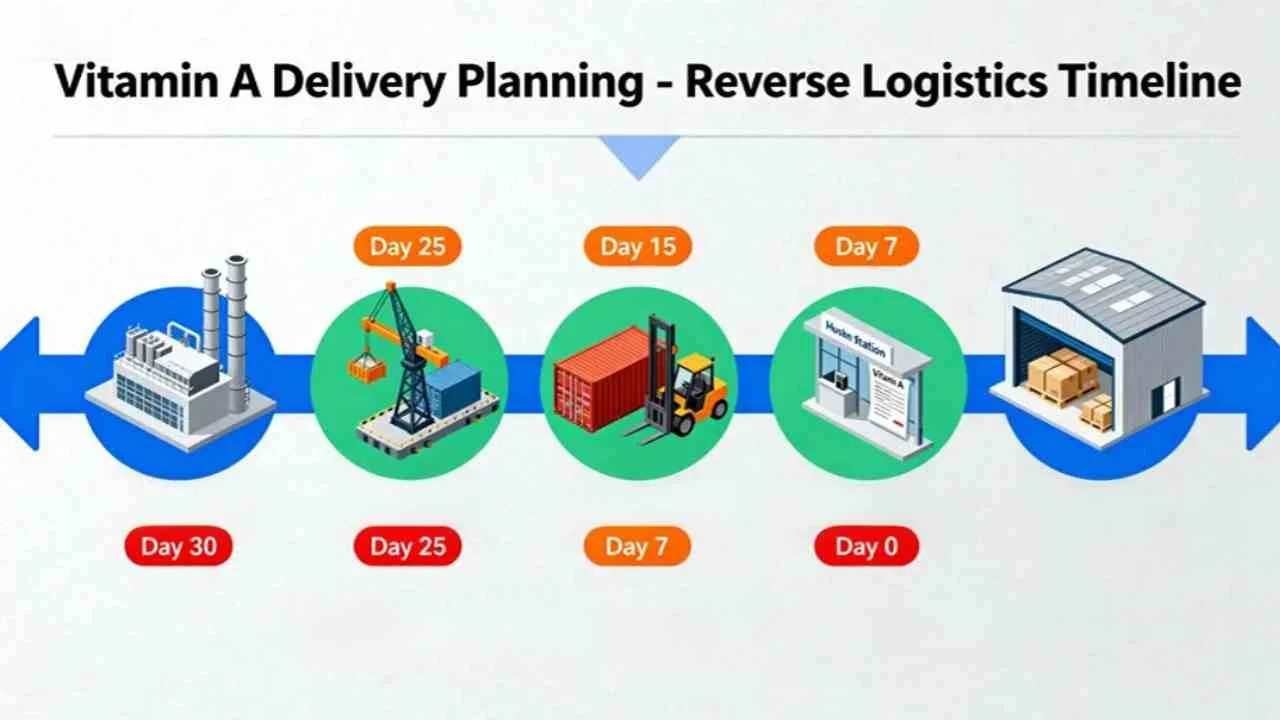

Reliable suppliers plan delivery using a "reverse timeline" method. They start with the buyer's required arrival date and work backward, calculating and scheduling each step: sea freight transit time, customs clearance, and production lead time.

Professional planning is essential. We use the reverse timeline method3, starting with your required delivery date and working backward. For example, if you need goods on July 30, we subtract the time for inland transit, customs, sea freight, and production to get a firm start date for manufacturing. This creates clear deadlines for every step. We also build in a buffer of a few days to absorb small, unexpected issues, ensuring that minor problems do not cause a major delay for you.

Sample Delivery Timeline (Working Backward):

| Milestone | Required Date | Lead Time | Action Must Be Completed By |

|---|---|---|---|

| Goods Arrive at Your Factory | July 30 | ||

| Ship Sails from Origin | June 27 | 25 days | June 27 |

| Production & QC Complete | June 10 | 10 days | June 10 |

Which routes are reliable for Vitamin A shipping?

You are offered a cheaper shipping option, but it involves multiple stops. Is it worth the risk? The shortest path is often the most reliable.

The most reliable shipping routes are direct sea freight services from major origin ports (like Shanghai) to major destination hubs (like Jebel Ali). These routes, offered by top-tier carriers, minimize transshipment points, which are the biggest sources of delay.

The most reliable route is a direct sailing4. The biggest risk in ocean freight is transshipment, where your container is moved from one ship to another at an intermediate port. Each transshipment increases the risk of delays, rolled cargo, or even loss. I always prioritize booking direct sailings for my clients. We also partner with top-tier carriers like Maersk and MSC, as they have more reliable schedules and better service than smaller, budget lines.

Shipping Route Reliability Comparison:

| Route Type | Key Characteristics | Risk of Delay | Typical Reliability |

|---|---|---|---|

| Direct Sailing | No transshipments, single vessel journey. | Low | High |

| Transshipment | Container is moved between ships. | Medium-High | Low-Medium |

How can logistics reduce Vitamin A delays?

The ship has been booked. Is everything now out of your hands? Not at all. Proactive logistics management is about preventing problems before they can cause a delay.

Professional logistics management reduces delays by ensuring all export documentation is 100% accurate and submitted on time. It is about preventing paperwork-related holds at customs, which are the most common and avoidable source of delays.

Many delays are caused by simple human error. The most common cause is incorrect documentation5. A single typo on the Bill of Lading or a wrong HS code on the commercial invoice can cause customs to hold your container for weeks. We prevent this with a strict multi-step verification process for all paperwork before the ship sails. We also work with experienced freight forwarders6 who are experts at navigating port and customs procedures, ensuring a smooth process from start to finish.

Key Logistics Actions to Prevent Delays:

| Action | Purpose | Consequence of Failure |

|---|---|---|

| Pre-Verify All Documents | To ensure 100% accuracy before submission. | Customs hold, fines, shipment rejection. |

| Partner with a Pro Forwarder | To have an expert manage the complex process. | Poor communication, inability to solve problems. |

Why track Vitamin A shipments in real time?

Your supplier tells you the ship has sailed. Then, silence for three weeks. This uncertainty is stressful and makes planning impossible. There is a better way.

Real-time tracking is vital because it provides complete visibility of the shipment's location and Estimated Time of Arrival (ETA). This allows the buyer to plan production confidently and enables proactive management of any unforeseen delays.

Real-time tracking turns reactive panic into proactive planning. Instead of finding out about a delay when the container fails to arrive, we can see a potential problem developing days or weeks in advance. This allows us to proactively inform you with a new, realistic ETA so you can adjust your production schedule. This transparency is key. It builds trust and turns a potential crisis into a manageable event.

Benefits of Real-Time Tracking:

| Feature | Benefit for the Buyer |

|---|---|

| Live Vessel Location | Confident production planning based on real data. |

| Updated ETA | Ability to adjust schedules proactively. |

| Full Transparency | Reduces anxiety and builds trust. |

Conclusion

On-time delivery is not a bonus feature; it is a fundamental promise. It requires meticulous planning, smart logistics, and transparent communication to protect your production and your business.

-

Understanding the impacts of production shutdown can help businesses mitigate risks and improve operational efficiency. ↩

-

Exploring the effects of reputational damage can provide insights into maintaining customer trust and long-term success. ↩

-

Understanding the reverse timeline method can enhance your project management skills and ensure timely delivery. ↩

-

Exploring this link will provide insights into why direct sailings are crucial for timely and secure shipping. ↩

-

Understanding the effects of incorrect documentation can help you avoid costly delays and ensure smooth shipping operations. ↩

-

Exploring the role of freight forwarders can provide insights into how they streamline shipping processes and enhance efficiency. ↩